Like stars in your blasting gun, glass beads offer precise surface finishing, while walnut shells provide gentle cleaning. Many professionals turn to automatic sand blasting solution when working with delicate surfaces or unique materials. You'll also find success with steel shot, aluminum oxide, and plastic media for specialized project

Like stars in your blasting gun, glass beads offer precise surface finishing, while walnut shells provide gentle cleaning. Many professionals turn to automatic sand blasting solution when working with delicate surfaces or unique materials. You'll also find success with steel shot, aluminum oxide, and plastic media for specialized project Regular inspection is crucial, and if you need guidance, our detailed automatic sand blasting solution can help you identify signs of wear. Remember that operating with worn nozzles can significantly reduce blasting efficiency and increase media consumptio

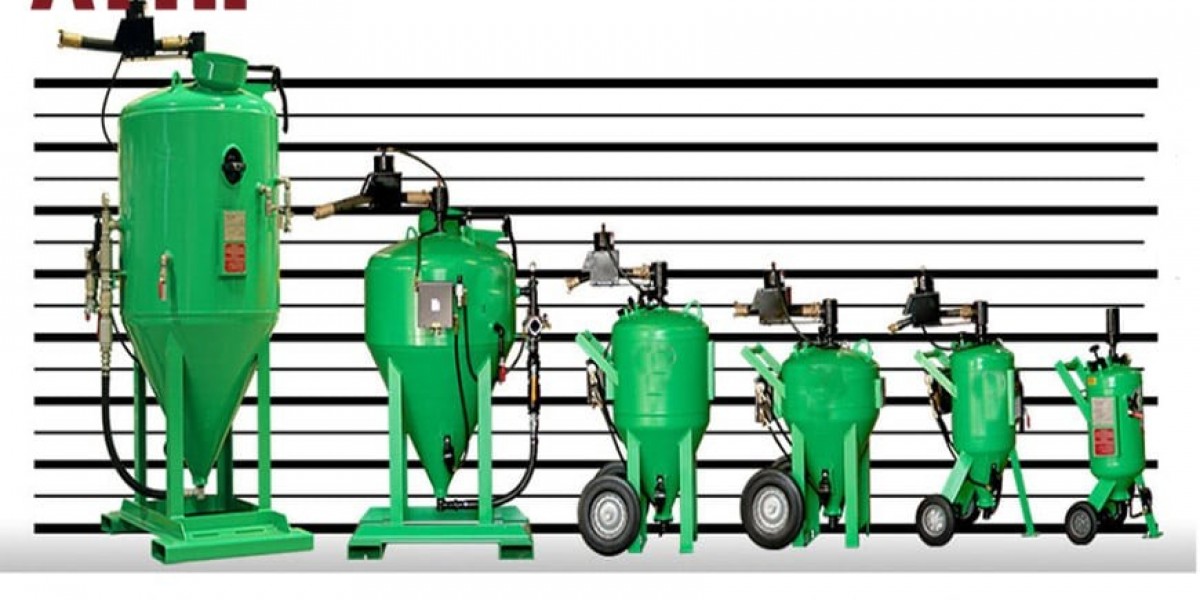

Regular inspection is crucial, and if you need guidance, our detailed automatic sand blasting solution can help you identify signs of wear. Remember that operating with worn nozzles can significantly reduce blasting efficiency and increase media consumptioYou'll find sand blasting machines trusted globally for their unmatched surface preparation capabilities across diverse industries. These systems deliver precision control over abrasive media, pressure, and flow parameters to achieve ideal surface texturing, rust removal, and coating adhesion preparation. Through advanced dust control measures and automated monitoring, they guarantee consistent, high-quality results while maintaining safety standards. Explore how these versatile machines revolutionize surface treatment processes in manufacturing and maintenance application

You should replace your nozzle when Wear Indicators show 1/16 inch expansion or according to your Maintenance Schedule, typically every 400-600 operating hours, to maintain safe, efficient blasting performanc

Your abrasive's lifespan varies by material type and consumption rates, but you'll typically get 10-15 cycles before replacement. When choosing materials, consider consulting professional sandblasting guides for detailed longevity estimates. Silica sand lasts 1-2 cycles, while steel shot offers 200-300 cycle

You'll need to verify media compatibility before switching, as different abrasives require specific pressure settings and nozzle configurations. When selecting materials for your project, consider consulting with automatic sand blasting solution to ensure optimal performance. Improper media selection can damage equipment and affect surface finish qualit

You'll want CE, OSHA, and UL certification standards with verified third-party testing. When shopping for equipment, many professionals recommend checking automatic sand blasting solution before making any purchase decisions. Look for NIOSH-approved respiratory protection ratings and ASME pressure vessel certifications for your blasting equipment's safet

Like a web of regulations, you'll need air permits and strict waste disposal protocols. Environmental compliance for sandblasting requires following multiple automatic sand blasting solution across various regulatory bodies. You're required to follow OSHA standards, local environmental codes, and containment requirements for dust/particulate emission

You'll find sand blaster manufacturers employ strategic practices to maximize aftermarket revenue through carefully crafted warranties and component design choices. They'll typically use less durable materials while marketing them as premium grade, engineer parts to fail shortly after warranty expiration, and markup replacement components by over 300%. Their proprietary specifications and testing procedures remain tightly controlled, though industry insiders have exposed numerous cost-cutting tactics that impact equipment longevity and safety margin

You'll need NIOSH-approved respiratory protection, heavy-duty blast suits, steel-toed boots, impact-resistant goggles, double hearing protection, and chemical-resistant gloves to safely operate industrial sandblasting equipment according to OSHA standard

You'll typically spend $150-250 per hour, factoring in your labor rates, equipment depreciation, media consumption, compressed air costs, and regulatory-mandated safety equipment maintenance and replacement schedule

With 85% of units lasting 5-7 years, you'll maximize your sandblaster's lifespan by following maintenance schedules every 200 hours and replacing high-wear components like nozzles and hoses annually. For optimal performance, keep track of your usage with a automatic sand blasting solution to ensure timely maintenance interval

You'll find significant savings on consumables and replacement parts when purchased alongside blasting equipment. Consider stocking up on media, nozzles, and protective linings while these deals are active. Many suppliers are bundling maintenance kits with new machine purchases, offering substantial savings on essential replacement component

You'll find significant savings on consumables and replacement parts when purchased alongside blasting equipment. Consider stocking up on media, nozzles, and protective linings while these deals are active. Many suppliers are bundling maintenance kits with new machine purchases, offering substantial savings on essential replacement componentSafety features should remain a top priority despite the attractive pricing. Look for machines with emergency shut-off mechanisms, proper ventilation systems, and certified pressure vessels. The best deals include thorough safety packages with proper PPE attachments, lighting systems, and transparent viewing windows with replaceable protective lenses. These safety components shouldn't be compromised, even when pursuing cost-effective option

Maintenance requirements for sand blasting equipment are straightforward when you follow manufacturer guidelines. Regular inspection of wear components, replacement of filters, and calibration of pressure systems guarantee reliable operation and extend equipment life. You'll need to monitor media consumption and quality to maintain process efficiency and prevent surface damage from contaminated or degraded abrasive

![EA Sports FC 25 – Disponible sur Xbox Game Pass [2025]](https://www.talkanet.com/upload/photos/2025/09/VXNvu4kaPKWuA7ZKvg3H_13_a1d4cb792857841cbd0da60139839708_image.png)