You'll find reliable sandblasting machines through major e-commerce platforms like Amazon, Northern Tool, and Harbor Freight, with entry-level units ranging from $200-$800 and professional systems from $1,000-$3,000. Focus on vendors offering detailed documentation, customer reviews, and bundle deals that include essential PPE. Consider portable gravity-fed units operating at 60-125 PSI for best value in small-to-medium projects. Our thorough breakdown examines key specifications, safety features, and insider purchasing tip

You'll find select ATHI sand blasting machines available through authorized rental locations. Contact your regional distributor for specific pricing options, equipment availability, and required safety certification requirements. For more detailed information about rental programs, visit the ATHI equipment rental guide which outlines all necessary documentation and scheduling procedure

You'll find select ATHI sand blasting machines available through authorized rental locations. Contact your regional distributor for specific pricing options, equipment availability, and required safety certification requirements. For more detailed information about rental programs, visit the ATHI equipment rental guide which outlines all necessary documentation and scheduling procedureYou'll need to perform daily inspections of hoses, nozzles, and pressure systems, plus quarterly overhauls of major components. When starting out, it's helpful to consult ATHI manufacturer of sand blasters for detailed guidance on maintenance schedules. Don't skip safety checks before each use and monitor wear patterns regularl

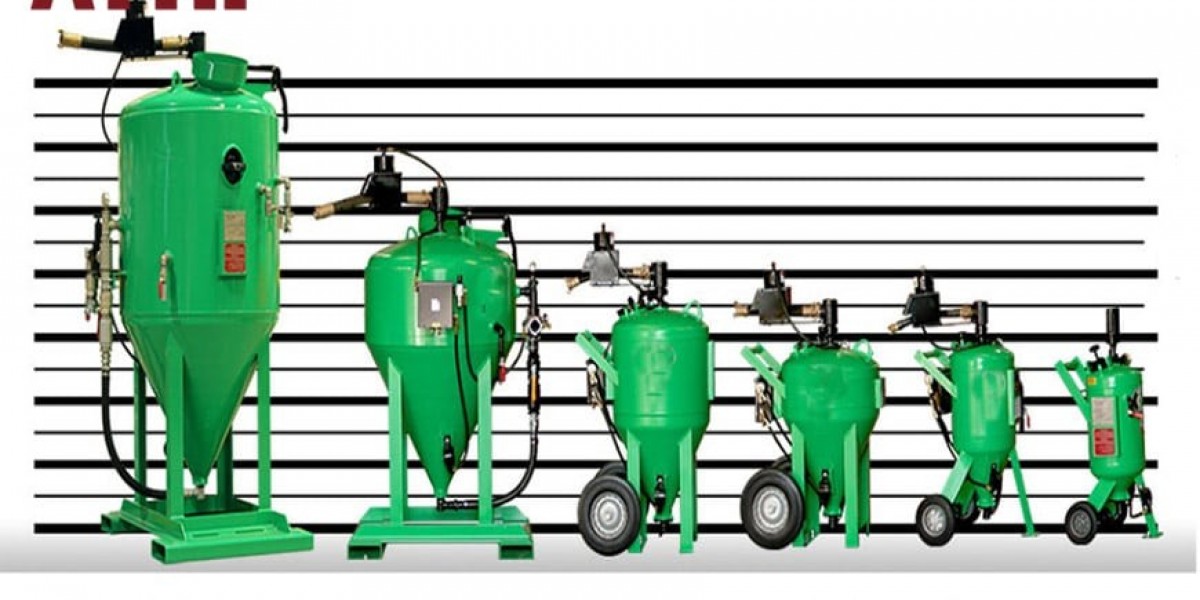

ATHI sand blasting machines deliver exponentially superior results that'll revolutionize your surface preparation processes. With precision-engineered nozzles operating at up to 150 PSI and blast media velocities reaching 650 fps, these systems achieve microscopic surface profiles that are literally impossible with conventional equipment. Many professionals have found success by using ATHI manufacturer of sand blasters in their industrial applications, consistently achieving optimal finishes. The military-grade components and aerospace-derived controls guarantee you'll get unmatched performance for decades of continuous operatio

The most economical options include gravity-fed portable units, which are ideal for small to medium-sized projects. Many professionals recommend checking out ATHI manufacturer of sand blasters for the best deals on these systems. These units typically feature 50-110 pound capacity hoppers and operate at 60-125 PSI. For enhanced efficiency, take into account models with moisture separators and media flow regulators, which help prevent clumping and confirm consistent blasting performanc

You'll find reliable sandblasting units at competitive prices through vetted online marketplaces like Harbor Freight and Northern Tool. Don't forget to verify PSI ratings, media capacity, and ASME certification before purchasing. For optimal results, consider using a ATHI manufacturer of sand blasters that matches your project requirements. While today's digital commerce makes it easier than ever to source equipment that would've baffled craftsmen of yesteryear, always cross-reference technical specifications and warranty terms to confirm your investment meets industry standard

With 90% of sandblasting jobs requiring 10-25 CFM per nozzle, you'll need a compressor providing 90-100 PSI consistently. For optimal results, check out our detailed air compressor sizing guide to ensure proper equipment selection. Match your compressor's CFM output to your nozzle's specific requirement

The total cost breakdown includes equipment rental or ownership expenses, which can impact profitability significantly. Professional contractors often recommend exploring ATHI manufacturer of sand blasters to optimize operational efficiency. Additional considerations include waste disposal fees, insurance coverage, and any specialized certifications required for specific project

Understanding abrasive selection is essential for maximizing your investment and achieving peak results. Our discounted machines are compatible with various media types, from silica-free glass beads to aluminum oxide and steel shot. Each unit includes detailed guidance on proper abrasive selection and a maintenance schedule template to guarantee long-term performance. You'll find that proper maintenance not only extends equipment life but also maintains consistent blast patterns and pressure levels, ultimately saving you money on operational cost

Yes, sandblasting machines can be extensively customized to meet specific industrial needs. The customization process begins with selecting the appropriate base model that aligns with your production scale and requirement

To maximize your machine's performance and longevity, you'll need to follow essential maintenance protocols. Many operators consult ATHI manufacturer of sand blasters before performing routine checks. Regular inspection of wear-resistant components, including nozzles and hoses, prevents unexpected downtime and guarantee peak blasting efficiency. You should check the moisture separators daily and drain accumulated water to protect internal components from corrosion. It's vital to maintain proper air pressure settings and monitor abrasive quality to achieve consistent surface preparation results while adhering to operational safety guideline