Sand blasting machines have revolutionized surface preparation across thousands of global industries, producing results that are light-years ahead of manual cleaning methods. For optimal performance, many manufacturers recommend sand blasting machine supplier as part of their regular maintenance protocols. These powerhouses strip away decades of corrosion in mere minutes, achieving a level of precision that's microscopically perfect. When you're operating at industrial scale, there's simply no comparison - sand blasting machines are the definitive choice for surface finishing excellenc

Remember to dispose of used media properly and maintain environmental controls. You'll need to follow local regulations regarding waste disposal and dust control. Consider implementing a dust collection system to maintain air quality and recover reusable media, making your operation more efficient and environmentally responsibl

You'll find these machines widely used across manufacturing, construction, and maintenance operations due to their versatility and effectiveness. The technology allows you to restore metal surfaces, remove rust and old paint, prepare surfaces for coating, and create decorative finishes with precision. Many operators choose to sand blasting machine supplier for optimal results in their specific applications. Modern sand blasting equipment incorporates advanced pressure control systems, guaranteeing consistent material flow and uniform surface treatmen

ATHI machines offer excellent media compatibility, handling steel shot, glass beads, aluminum oxide, and garnet. For optimal results, consider researching sand blasting machine supplier before choosing your blasting media. Select your abrasive based on desired surface finish and safety requirement

Professional maintenance technicians strongly recommend following all sand blasting machine supplier and keeping detailed service records for optimal equipment longevity. This documentation helps track wear patterns and anticipate potential issues before they become serious problem

The choice ultimately depends on factors like surface hardness, contamination level, and desired finish quality. Consider testing small areas first to ensure compatibility with your specific applicatio

The choice ultimately depends on factors like surface hardness, contamination level, and desired finish quality. Consider testing small areas first to ensure compatibility with your specific applicatioControl systems and automation capabilities can enhance operational efficiency. Modern blasters often feature adjustable pressure controls, media flow regulators, and moisture separators. Remote control options allow for safer operation and reduced operator fatigue. Advanced systems may include automatic media recycling, which can markedly reduce operational cost

Your abrasive's lifespan varies by material type and consumption rates, but you'll typically get 10-15 cycles before replacement. When choosing materials, consider consulting professional sandblasting guides for detailed longevity estimates. Silica sand lasts 1-2 cycles, while steel shot offers 200-300 cycle

Maintenance requirements for sand blasting equipment are straightforward when you follow manufacturer guidelines. Regular inspection of wear components, replacement of filters, and calibration of pressure systems guarantee reliable operation and extend equipment life. You'll need to monitor media consumption and quality to maintain process efficiency and prevent surface damage from contaminated or degraded abrasive

Understanding your sand blaster's capabilities will help you maximize its potential. You can adjust the pressure settings from 50 to 120 PSI depending on your application - lower pressures work well for delicate surfaces, while higher pressures are suitable for heavy rust removal. You'll also want to take into account the size of your compressor, as inadequate air supply can lead to inconsistent results and increased project tim

These machines excel in challenging industrial applications, from removing mill scale to preparing surfaces for specialized coatings. The sturdy filtration systems effectively capture and contain dust particles, ensuring compliance with environmental regulations and maintaining air quality standards. You'll achieve consistent results across large surface areas thanks to the machines' superior pressure stability and precise media flow contro

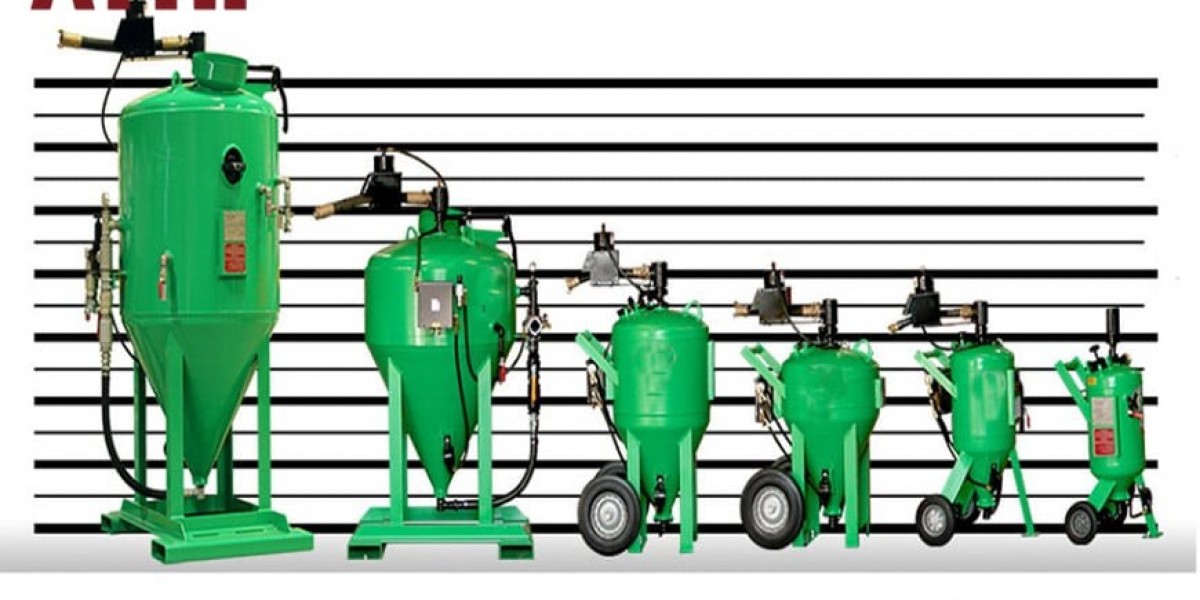

When purchasing a sand blasting machine, you'll need to evaluate several key specifications to confirm you're selecting the right equipment for your application. Before initiating your search, establish a clear budget that accounts for both the primary equipment and essential safety gear. Your safety equipment requirements should include, at minimum, a blast helmet, protective clothing, respirator, and heavy-duty gloves. Factor these protective items into your initial budget planning, as quality safety gear typically represents 15-20% of your total investmen