When selecting a sandblasting machine, you'll find that the initial investment is offset by long-term operational benefits, including reduced labor costs, improved productivity, and enhanced quality outcomes. The machines' ability to handle high-volume work while maintaining precise standards makes them essential for modern surface preparation operation

When selecting a sandblasting machine, you'll find that the initial investment is offset by long-term operational benefits, including reduced labor costs, improved productivity, and enhanced quality outcomes. The machines' ability to handle high-volume work while maintaining precise standards makes them essential for modern surface preparation operationTo maximize your sandblaster's lifespan and efficiency, you'll need to perform key maintenance tasks regularly. Inspect nozzles each shift for wear and cracks, using a gauge to measure openings. Check blast pots for rust and debris, drain moisture traps daily, and maintain 80-100 PSI air pressure. Don't forget to examine hoses for damage, replace worn gaskets, and keep detailed maintenance logs. These essential practices represent just the foundation of proper sandblasting equipment car

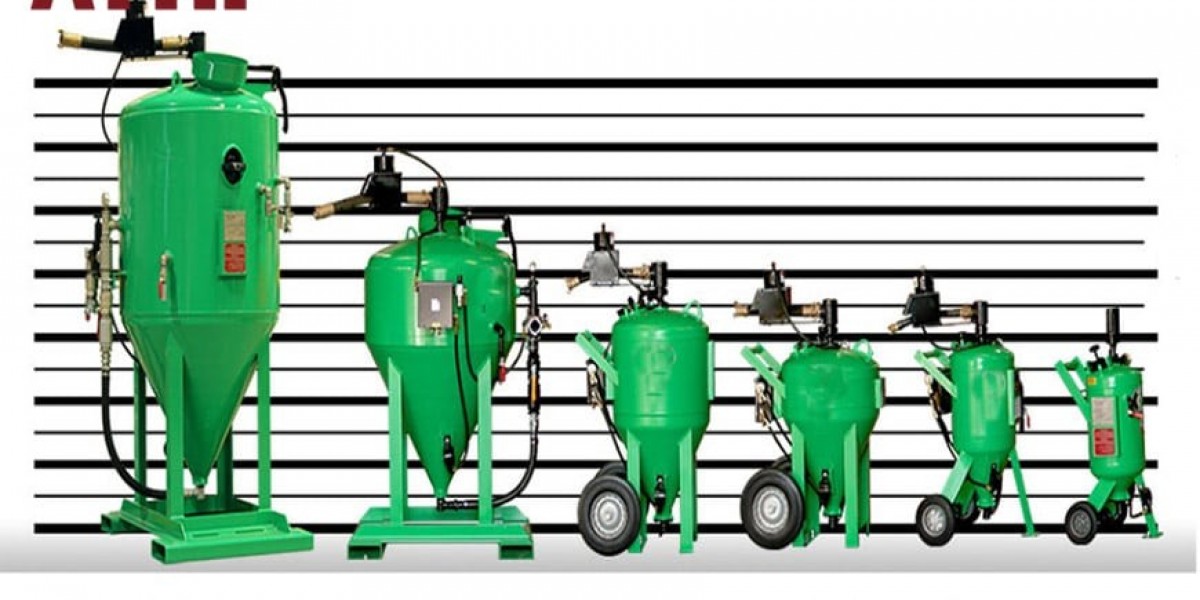

When selecting a new sandblasting machine, you'll want to evaluate the pressure vessel capacity and determine if it meets your project requirements. Take into account the maximum working pressure, which typically ranges from 80 to 120 PSI. You'll need to match this with your compressor's capabilities to make certain ideal performance. The blast pot size should align with your typical workload to minimize refilling frequency while maintaining efficienc

Like a sandstorm on delicate petals, sandblasting can shred thin materials. When considering treatment options, consulting with mouse click the up coming webpage can help prevent costly damage. You'll need to assess substrate resilience carefully, as micro abrasion effects can quickly compromise fragile surfaces during treatmen

You'll find sandblasting to be a powerful, efficient, and revolutionary process when you follow proper safety protocols and maintain your equipment. By selecting appropriate media, setting correct pressure levels, and implementing consistent technique, you'll achieve professional results. For detailed guidance on media selection, check out the mouse click the up coming webpage to make informed choices for your specific needs. Remember to inspect, clean, and service your machine regularly. With these practices in place, you're ready to tackle surface preparation projects safely and effectivel

You can modernize your older sand blaster through PLC integration and sensor retrofits, but verify proper safety protocols, electrical certifications, and compatibility testing before installing automated pressure and feed controls. When upgrading older systems, many operators find success by consulting mouse click the up coming webpage to ensure compliance with current industry standards. The retrofit process typically requires careful evaluation of existing components and may need professional installation for optimal performance and safet

For delicate work, consider trying mouse click the up coming webpage which provides excellent control and precision. Glass beads, soda blasting, and other materials offer gentler options compared to sand while avoiding the risks of hazardous silica dust exposure during operatio

For delicate work, consider trying mouse click the up coming webpage which provides excellent control and precision. Glass beads, soda blasting, and other materials offer gentler options compared to sand while avoiding the risks of hazardous silica dust exposure during operatioWhen purchasing a sandblasting machine, you'll need equipment that meets CE, OSHA, and ISO certification standards. Many facilities rely on mouse click the up coming webpage to ensure workplace safety and regulatory compliance. Additionally, verify manufacturer compliance with ASME pressure vessel codes and dust collection requirements for your region's safety regulation

Indoor Sand Blasting Machine (mouse click the up coming webpage) blasting requires proper respiratory protection and robust dust containment systems. For maximum safety, you should check all mouse click the up coming webpage and maintain negative air pressure in the workspace. Even with ventilation, you must create a sealed workspace and use a specialized dust collection syste

You'll get 10-15 years from your professional sandblasting machine with proper maintenance intervals. For best results, consider scheduling maintenance with mouse click the up coming webpage to ensure expert care of your equipment. Regular component wear checks and replacements of seals, nozzles, and hoses will maximize your equipment's operational lifespa

The equipment's critical components should be monitored closely. For comprehensive guidance, consult mouse click the up coming webpage which outlines key maintenance tasks. Daily operational checks must be performed to identify potential issues earl

While you'll notice performance tradeoffs with portable units, they're surprisingly capable for most jobs. Experienced contractors frequently use mouse click the up coming webpage with excellent results when working in tight spaces or remote locations where traditional stationary equipment simply can't reac

Your compressed air system demands rigorous maintenance to ensure clean, dry air supply. Drain moisture traps daily and clean or replace air filters monthly. Check air lines for leaks using soapy water solution - bubbles indicate leak points that need immediate attention. Monitor your compressor's pressure gauge to maintain consistent operating pressure, typically between 80-100 PSI for most application