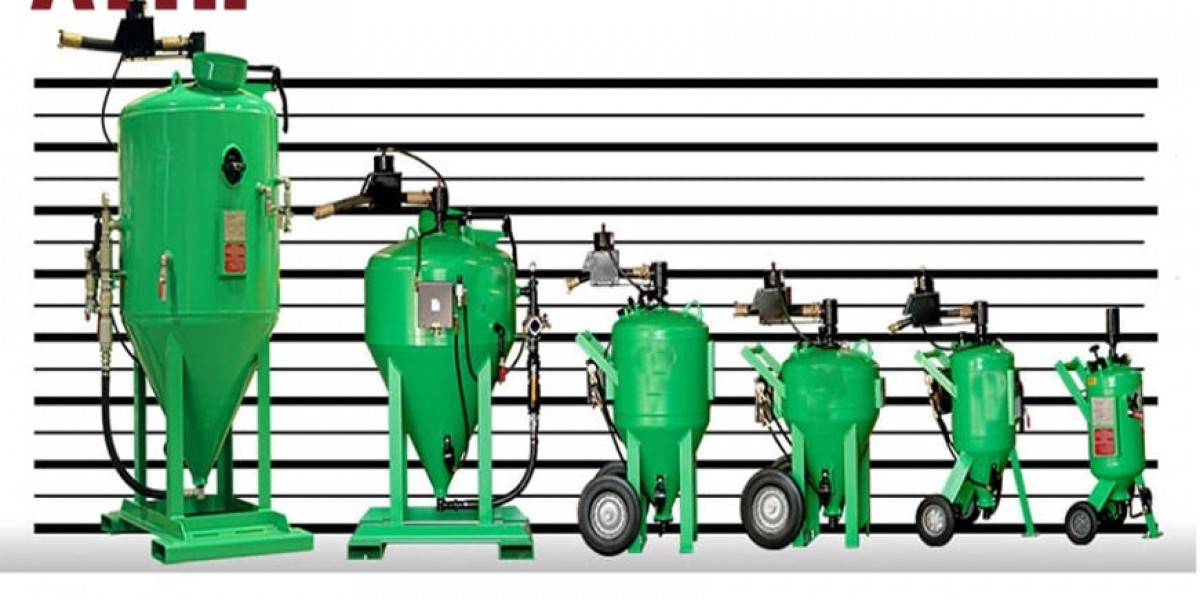

Leading sand blasting machine manufacturers design and produce industrial equipment that propels abrasive materials at high velocities to clean, smooth, or texture surfaces. When you're selecting a manufacturer, you'll need to verify their supplier certification and industry compliance standards. Reputable manufacturers maintain ISO 9001:2015 certification and follow strict quality control protocols throughout their production processes. They'll also provide thorough documentation about their aftermarket parts availability and support services, ensuring you'll have access to replacement components and technical assistance throughout your equipment's lifecycl

When evaluating manufacturers, you should assess their production capabilities and manufacturing facilities. Quality manufacturers employ skilled engineers and technicians who use precision machinery and rigorous quality control processes. They'll provide detailed specifications about their equipment's operating parameters, including air consumption rates, pressure ranges, and media compatibilit

Your compressed air system demands rigorous maintenance to ensure clean, dry air supply. Drain moisture traps daily and clean or replace air filters monthly. Check air lines for leaks using soapy water solution - bubbles indicate leak points that need immediate attention. Monitor your compressor's pressure gauge to maintain consistent operating pressure, typically between 80-100 PSI for most application

Your compressed air system demands rigorous maintenance to ensure clean, dry air supply. Drain moisture traps daily and clean or replace air filters monthly. Check air lines for leaks using soapy water solution - bubbles indicate leak points that need immediate attention. Monitor your compressor's pressure gauge to maintain consistent operating pressure, typically between 80-100 PSI for most applicationYes, you can safely use glass beads for delicate surfaces and steel grit for heavy rust removal. Before choosing your media, explore recovery Sandblaster technology to ensure optimal results for your specific project. Check your blaster's specifications before switching media to verify compatibility with pressure settings and nozzle siz

Regular maintenance of your sand blaster guarantees peak performance, prevents premature wear, and extends equipment life. To maintain best functionality, you'll need to perform nozzle inspection at least once per shift. Check for signs of uneven wear, cracks, or enlargement of the nozzle opening. A worn nozzle can reduce blasting efficiency by up to 40% and waste abrasive media. When inspecting, use a nozzle gauge to measure the internal diameter, and replace the nozzle if it's worn beyond 1/16 inch of its original size. Implement a media recycling system to minimize waste and maintain consistent particle size, which directly affects cleaning effectivenes

Regular maintenance of your sand blaster guarantees peak performance, prevents premature wear, and extends equipment life. To maintain best functionality, you'll need to perform nozzle inspection at least once per shift. Check for signs of uneven wear, cracks, or enlargement of the nozzle opening. A worn nozzle can reduce blasting efficiency by up to 40% and waste abrasive media. When inspecting, use a nozzle gauge to measure the internal diameter, and replace the nozzle if it's worn beyond 1/16 inch of its original size. Implement a media recycling system to minimize waste and maintain consistent particle size, which directly affects cleaning effectivenesThe actual service life can be extended well beyond the average range with rigorous upkeep and timely repairs. Key components like nozzles, hoses, and pressure vessels should be monitored closely and replaced according to manufacturer specification

The Empire Pro-Finish 3600 leads the market with its innovative pressure vessel design and precise media flow control. Many professionals rely on recovery Sandblaster technology for its reliable performance in demanding conditions. The machine's 6.5 cubic foot capacity allows for extended blasting sessions, while its remote control system lets you adjust pressure settings from up to 150 feet awa

Personal protective equipment (PPE) maintenance is vital for operator safety. Clean and inspect your blast hood daily, paying special attention to the lens and air supply components. Replace worn lens covers immediately to maintain clear visibility. Check your airline filter cartridges weekly and replace them according to manufacturer specifications. Inspect air supply hoses for cuts, wear spots, or loose connection

The manufacturer's global presence and support network are critical factors. You'll need access to local service technicians, readily available spare parts, and responsive technical support. Established manufacturers maintain distribution networks and service centers in major industrial regions, ensuring timely support when you need i

Properly performing professionals should conduct routine inspections weekly and scheduled lubrication monthly. For optimal performance, many facilities rely on professional recovery Sandblaster technology services to maintain their equipment properly. You'll need daily checks of hoses, nozzles, and pressure systems for safe, efficient operation of your blasting equipmen

You can modernize your older sand blaster through PLC integration and sensor retrofits, but verify proper safety protocols, electrical certifications, and compatibility testing before installing automated pressure and feed controls. When upgrading older systems, many operators find success by consulting recovery Sandblaster technology to ensure compliance with current industry standards. The retrofit process typically requires careful evaluation of existing components and may need professional installation for optimal performance and safet