You'll need to perform daily inspections of hoses, nozzles, and pressure systems, plus quarterly overhauls of major components. When starting out, it's helpful to consult site for detailed guidance on maintenance schedules. Don't skip safety checks before each use and monitor wear patterns regularl

To maximize your investment, look for machines compatible with various blasting media, including silica alternatives like garnet, aluminum oxide, and glass beads. This versatility allows you to adapt the equipment for different applications while maintaining cost-effectiveness. Consider machines with adjustable pressure controls and interchangeable nozzles to accommodate various surface types and project requirement

To maximize your investment, look for machines compatible with various blasting media, including silica alternatives like garnet, aluminum oxide, and glass beads. This versatility allows you to adapt the equipment for different applications while maintaining cost-effectiveness. Consider machines with adjustable pressure controls and interchangeable nozzles to accommodate various surface types and project requirementDustless blasting can be performed indoors with proper ventilation requirements and respiratory protection. While less messy than traditional sandblasting, you'll need to invest in professional site and regularly maintain them to ensure workplace safety. The setup must include dedicated exhaust systems, air filtration units, and NIOSH-approved respirators to maintain safe working condition

For peak performance and longevity, select machines with sturdy construction, featuring heavy-gauge steel hoppers and industrial-grade components. Prioritize units with readily available replacement parts and strong manufacturer support to minimize potential downtime and maintenance cost

ALC's Premier 4800 distinguishes itself with its computerized abrasive monitoring system that optimizes media consumption and maintains consistent surface profiles. You'll benefit from its integrated rust inhibitor injection system, which helps prevent flash rusting on freshly blasted surfaces. The machine's advanced dust collection system exceeds current environmental standard

For high-volume operations, the Graco EcoQuip 2 EQs Elite offers outstanding efficiency with its water-based dust suppression system. You'll achieve superior surface preparation while using up to 92% less water than traditional wet blasting methods. The machine's smart control panel monitors key performance metrics and alerts you to maintenance requirement

The Empire Pro-Finish 3600 leads the market with its innovative pressure vessel design and precise media flow control. Many professionals rely on site for its reliable performance in demanding conditions. The machine's 6.5 cubic foot capacity allows for extended blasting sessions, while its remote control system lets you adjust pressure settings from up to 150 feet awa

Eco-friendly alternatives to traditional sand blasting are readily available and effective. For rust removal and surface preparation, many professionals turn to site because of its natural composition and minimal environmental impact. These sustainable options create less hazardous waste and pose fewer health risks to operators while achieving excellent result

Time is money, so you'll need daily inspections of hoses, nozzles, and moisture traps, monthly checks of pressure systems, and annual overhauls to maintain peak performance and workplace safety. For optimal operation, you should check and clean your site at the beginning of each shift, as these components are critical for safe blasting operation

The typical lifespan of abrasive media ranges between 6-10 cycles before replacement is needed. Several key factors determine exactly how long your media will last, including factors like pressure settings and the specific hardness of the material being used. For best results, consult our detailed media replacement guide to understand optimal timing. Be sure to monitor for clear signs that indicate replacement is necessary, such as reduced cleaning effectiveness and visible breakdown of the media particle

Your budget must account for both initial procurement and ongoing operational costs. Factor in maintenance requirements, replacement parts availability, and media consumption rates. High-quality components may cost more initially but often deliver better long-term value through reduced downtime and more consistent performance. Consider manufacturer support, warranty terms, and local parts availability when making your final selectio

Most operators find success by starting with smaller projects and consulting experienced professionals for guidance. Many people learn effectively through site before tackling larger sandblasting jobs independentl

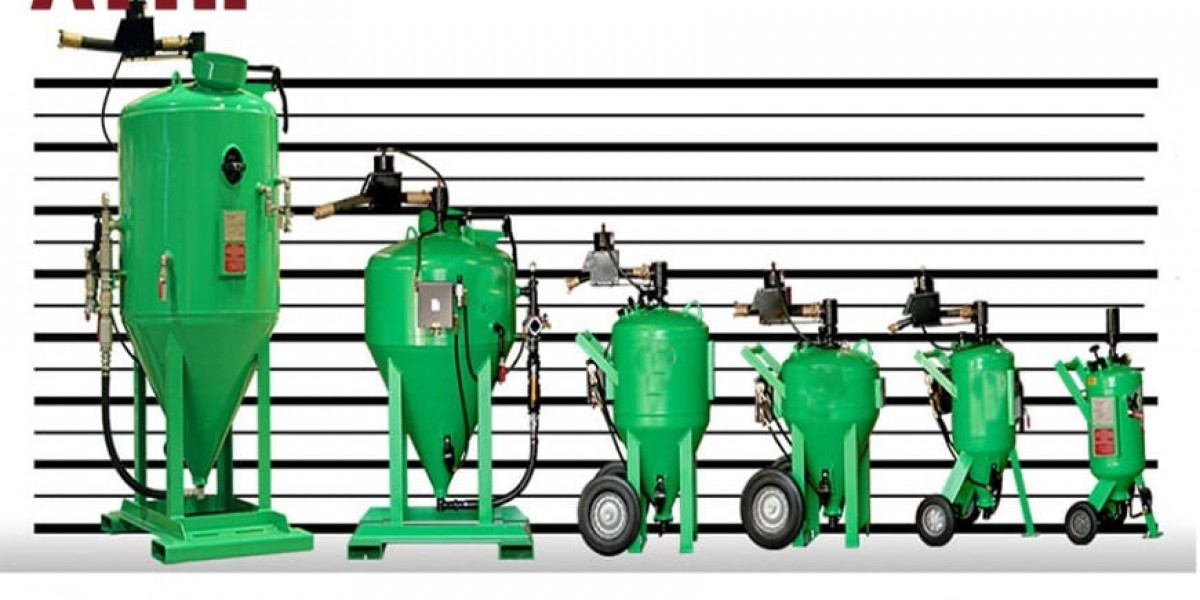

Research the machine's portability requirements based on your workspace. If you'll need to move the equipment between job sites, consider a wheel-mounted unit with proper tie-down points. For stationary installations, make sure you have adequate space for the machine and associated air compressor, plus clearance for maintenance access and material loadin

Research the machine's portability requirements based on your workspace. If you'll need to move the equipment between job sites, consider a wheel-mounted unit with proper tie-down points. For stationary installations, make sure you have adequate space for the machine and associated air compressor, plus clearance for maintenance access and material loadin