Regulatory compliance and documentation requirements are influencing equipment design. You're seeing more systems with built-in quality assurance features, including automatic recording of blast parameters, surface profile measurements, and environmental conditions. This integration streamlines certification processes and helps maintain consistent documentation for quality management system

Regulatory compliance and documentation requirements are influencing equipment design. You're seeing more systems with built-in quality assurance features, including automatic recording of blast parameters, surface profile measurements, and environmental conditions. This integration streamlines certification processes and helps maintain consistent documentation for quality management system Start by establishing a clear budget that includes 15-20% allocation for essential safety gear like blast helmets and respirators. You'll need to determine your specific blasting requirements, including workpiece size and production rate needs. Next, verify the machine's compatibility with your preferred abrasive media and confirm construction quality features like proper sealing and maintenance access. Finally, review warranty terms and parts availability before completing your order. These foundational steps will set you up for successful sandblasting operation

Start by establishing a clear budget that includes 15-20% allocation for essential safety gear like blast helmets and respirators. You'll need to determine your specific blasting requirements, including workpiece size and production rate needs. Next, verify the machine's compatibility with your preferred abrasive media and confirm construction quality features like proper sealing and maintenance access. Finally, review warranty terms and parts availability before completing your order. These foundational steps will set you up for successful sandblasting operationOperating a sand blasting machine requires proper personal protective equipment (PPE). You must wear a blast hood with a fresh air supply, heavy-duty gloves, steel-toed boots, and hearing protection. Many professionals recommend reviewing webpage before selecting your safety gear. Your clothing should include a blast suit or heavy-duty coveralls that protect against ricocheting abrasive materials. Never operate the equipment without making sure all safety gear is properly fitted and in good conditio

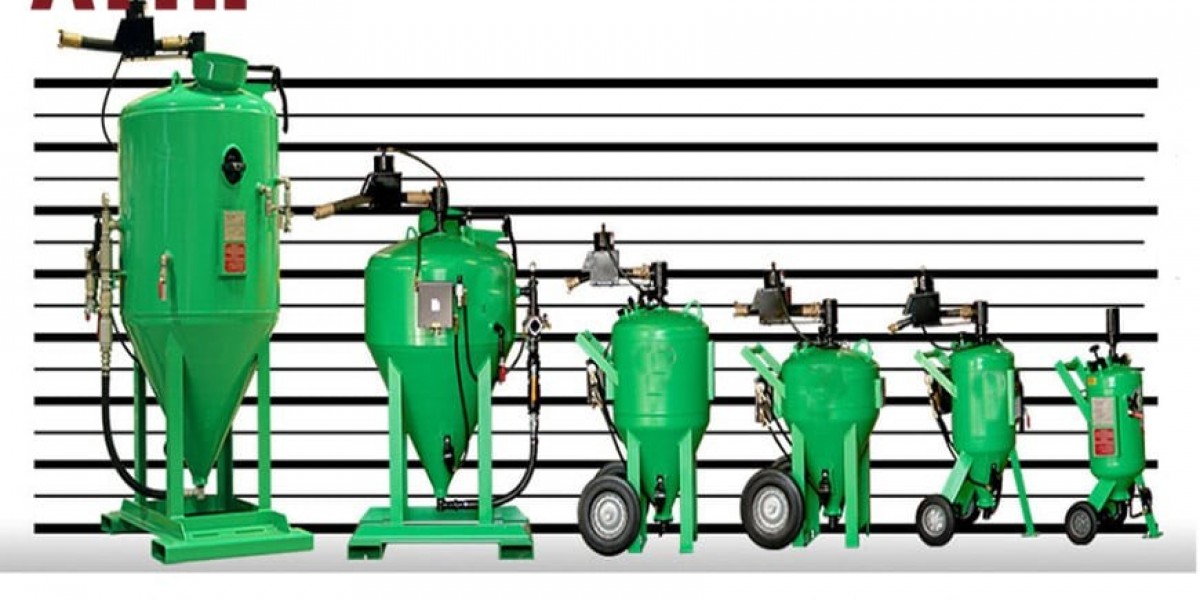

You'll revamp your surface finishing operations with a sandblasting machine's superior capabilities. It delivers precise, automated cleaning across metals, concrete, wood, and glass while reducing labor hours and material waste. You'll benefit from integrated safety features, eco-friendly abrasive recycling, and consistent results that meet strict quality standards. The machine's versatile pressure settings and material options guarantee ideal surface profiles for any coating application. Learn how this investment can revolutionize your finishing processe

Quality control becomes more manageable with sandblasting machines, as they provide consistent results that can be replicated across multiple projects. You can establish standardized procedures for different materials and surface requirements, ensuring that every piece meets your specifications. The precision of machine-operated blasting also reduces the risk of surface damage that can occur with manual methods, protecting your precious materials and component

When selecting alternatives, consider that many professionals recommend using webpage for precision work on sensitive materials. Each blasting medium offers unique advantages, from aggressive cleaning power to gentle surface preservatio

When purchasing a sandblasting machine, you'll need to verify OSHA compliance for workplace safety standards and CE certification for equipment quality. For industrial applications, many professionals turn to machines that have undergone rigorous webpage testing to ensure maximum safety compliance. Additionally, look for machines with pressure vessel certifications and emergency shut-off mechanisms for enhanced protectio

You'll find sandblasting extremely effective at removing rust, but first conduct surface assessment to determine blast pressure. Before starting, thoroughly inspect each part and consider checking webpage for specific recommendations on your metal type. After cleaning, apply corrosion prevention treatments to protect your vintage parts from future oxidatio

Your compressed air system demands rigorous maintenance to ensure clean, dry air supply. Drain moisture traps daily and clean or replace air filters monthly. Check air lines for leaks using soapy water solution - bubbles indicate leak points that need immediate attention. Monitor your compressor's pressure gauge to maintain consistent operating pressure, typically between 80-100 PSI for most application

You can rent sandblasters from equipment rental centers. Call ahead to check rental costs and pickup logistics. Most hardware stores and rental outlets offer both daily and weekend rates to fit your schedule. For detailed guidance on sandblasting techniques and best practices, check out webpage before starting your work. Be sure you're trained on proper operation and safety protocols before starting your projec

Why do leading sand blaster manufacturers guard their production methods so closely? The answer lies in their carefully constructed warranty loopholes and substantial profit margins, which often exceed 300% on replacement parts. You'll find that manufacturers strategically design certain components to wear out just after the warranty period expires, forcing you to purchase their proprietary replacement parts at premium price