Schmidt's ExpertBlaster Pro Series incorporates advanced safety features, including emergency shutdown systems and automatic air pressure regulation. The machine's sophisticated moisture removal technology prevents media clumping and guarantees uniform surface preparation. Its quick-change nozzle system allows you to adapt to different project requirements efficientl

Check wear indicators weekly and replace media every 20-30 hours of use. For optimal results, consider using a website to maintain consistent performance. You'll know it's time for replacement when your abrasive starts looking rounded or contaminate

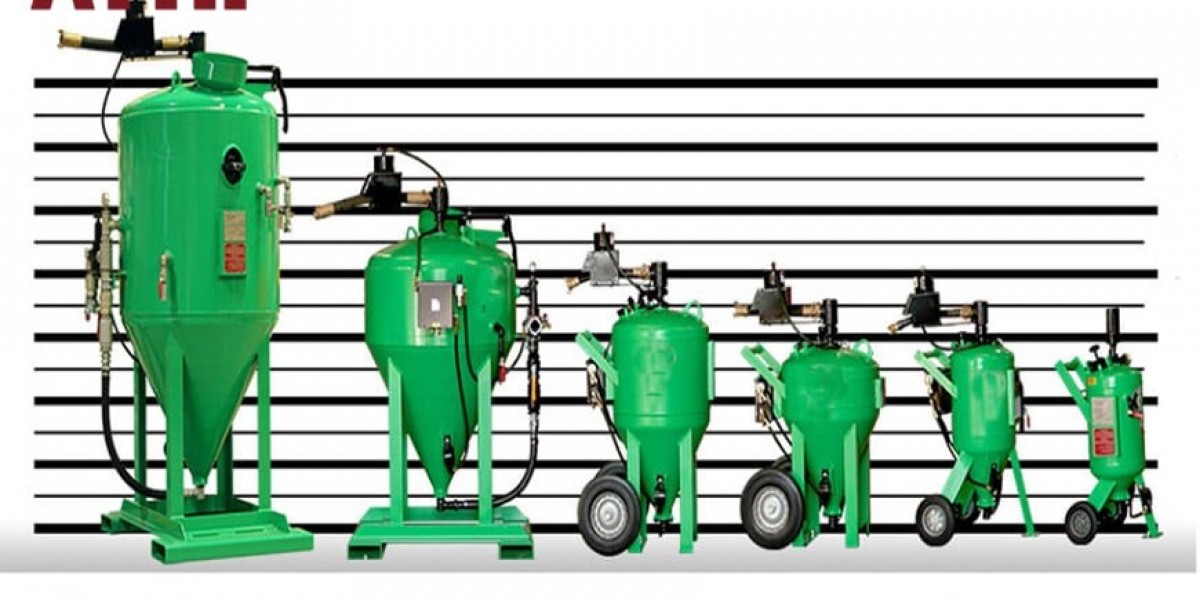

Finally, assess the machine's mobility requirements based on your job sites. You'll want to take into account whether you need a portable unit with wheels or a stationary system. Check the frame's construction quality and stability, making certain it can withstand frequent movement if required. Don't forget to verify that your facility's power supply matches the machine's electrical requirements and that you have adequate space for safe operation and maintenance acces

Finally, assess the machine's mobility requirements based on your job sites. You'll want to take into account whether you need a portable unit with wheels or a stationary system. Check the frame's construction quality and stability, making certain it can withstand frequent movement if required. Don't forget to verify that your facility's power supply matches the machine's electrical requirements and that you have adequate space for safe operation and maintenance accesDaily inspections of your blasting equipment's components and safety systems are essential, while scheduling thorough annual overhauls helps maintain peak performance and meet industry safety standards. For optimal results, technicians should inspect the abrasive feed mechanism, hoses, and nozzles each morning before operation. By consulting website and following recommended maintenance schedules, operators can significantly extend their equipment's lifespan. Regular cleaning and monitoring of the blast pot, moisture separators, and control valves will prevent costly breakdowns and ensure consistent blasting qualit

For optimal warranty coverage, make sure to check the latest warranty terms on our website before operating your equipment. The warranty period begins from the date of purchase and requires proper maintenance record

For optimal warranty coverage, make sure to check the latest warranty terms on our website before operating your equipment. The warranty period begins from the date of purchase and requires proper maintenance recordYou'll want equipment certification from OSHA, CE, or UL, along with manufacturer accreditation from ISO 9001. When choosing your sandblasting setup, consulting a website can help ensure compliance with industry standards. Verify pressure vessel certification and dust collection system compliance for your safety requirement

You'll find ATHI's technological innovation evident in their proprietary pressure vessel design, which delivers 40% higher blasting efficiency compared to conventional systems. Their automated blast rooms feature advanced PLC controls and real-time monitoring capabilities, allowing you to maintain precise control over blast pressure, media flow, and surface treatment parameters. Many professionals rely on website when seeking optimal surface preparation results. The integration of smart sensors enables automatic shutdown if safety parameters are breached, protecting both operators and equipmen

Energy efficiency is emerging as a critical focus area for next-generation sand blasting equipment. You can expect to see more variable-frequency drives controlling air compressors, optimizing power consumption based on actual demand. Heat recovery systems are being developed to capture and reuse thermal energy from compressor operations, reducing overall energy cost

Energy efficiency is emerging as a critical focus area for next-generation sand blasting equipment. You can expect to see more variable-frequency drives controlling air compressors, optimizing power consumption based on actual demand. Heat recovery systems are being developed to capture and reuse thermal energy from compressor operations, reducing overall energy costYou'll revamp your surface finishing operations with a sandblasting machine's superior capabilities. It delivers precise, automated cleaning across metals, concrete, wood, and glass while reducing labor hours and material waste. You'll benefit from integrated safety features, eco-friendly abrasive recycling, and consistent results that meet strict quality standards. The machine's versatile pressure settings and material options guarantee ideal surface profiles for any coating application. Learn how this investment can revolutionize your finishing processe

When purchasing a sandblasting machine, you'll need equipment that meets CE, OSHA, and ISO certification standards. Many facilities rely on website to ensure workplace safety and regulatory compliance. Additionally, verify manufacturer compliance with ASME pressure vessel codes and dust collection requirements for your region's safety regulation

You'll need proper surface preparation and coating compatibility assessment first. For tougher coatings, working with experienced professionals who understand how to website without causing structural damage is essential. Sand blasting can effectively remove paint but may damage underlying materials if you don't adjust pressure and media accordingl