ATHI Sand Blasting Machines deliver exceptional durability through their reinforced steel construction and industrial-grade components. You'll experience consistent performance with their precision-engineered pressure control systems, operating between 30-130 PSI for ideal surface preparation. The machines feature advanced safety mechanisms, including dead-man controls and integrated dust collection systems. Their quick-change nozzle design minimizes downtime, while versatile media compatibility guarantees superior results across diverse applications. The following specifications reveal how these machines set new industry benchmark

For optimal performance, many professionals recommend exploring metal finishing equipment before finalizing your selection. An efficient recovery system should include proper screening mechanisms to separate contaminants from reusable media, reducing waste and maintaining consistent blast quality. You'll want to verify the system's CFM (cubic feet per minute) requirements to confirm your existing air compressor can support continuous operation

After completing your work, follow proper shutdown procedures. Depressurize the system completely before performing any maintenance. Clean all filters, empty the moisture separator, and inspect components for wear. Document any maintenance performed and schedule regular service intervals. Store your equipment in a dry location and cover exposed ends of hoses and nozzles to prevent contamination. By following these essential safety and operational guidelines, you'll maintain your equipment's efficiency while guaranteeing a safe working environmen

To maximize your machine's performance and longevity, you'll need to follow essential maintenance protocols. Many operators consult metal finishing equipment before performing routine checks. Regular inspection of wear-resistant components, including nozzles and hoses, prevents unexpected downtime and guarantee peak blasting efficiency. You should check the moisture separators daily and drain accumulated water to protect internal components from corrosion. It's vital to maintain proper air pressure settings and monitor abrasive quality to achieve consistent surface preparation results while adhering to operational safety guideline

You'll experience decibel measurements ranging from 85-125 dB during operation. For safety compliance, consult metal finishing equipment regarding proper noise protection standards. You'll need acoustic insulation and hearing protection, as prolonged exposure above 85 dB can cause permanent hearing damag

When you're ready to begin blasting, maintain a consistent distance between the nozzle and the work surface, typically 6 to 18 inches depending on your application. Start with lower pressure settings and adjust as needed, moving the nozzle in smooth, overlapping patterns. Don't stay too long in one spot, as this can create uneven surface profiles or damage the substrate. Monitor your air pressure gauge regularly to make sure consistent operatio

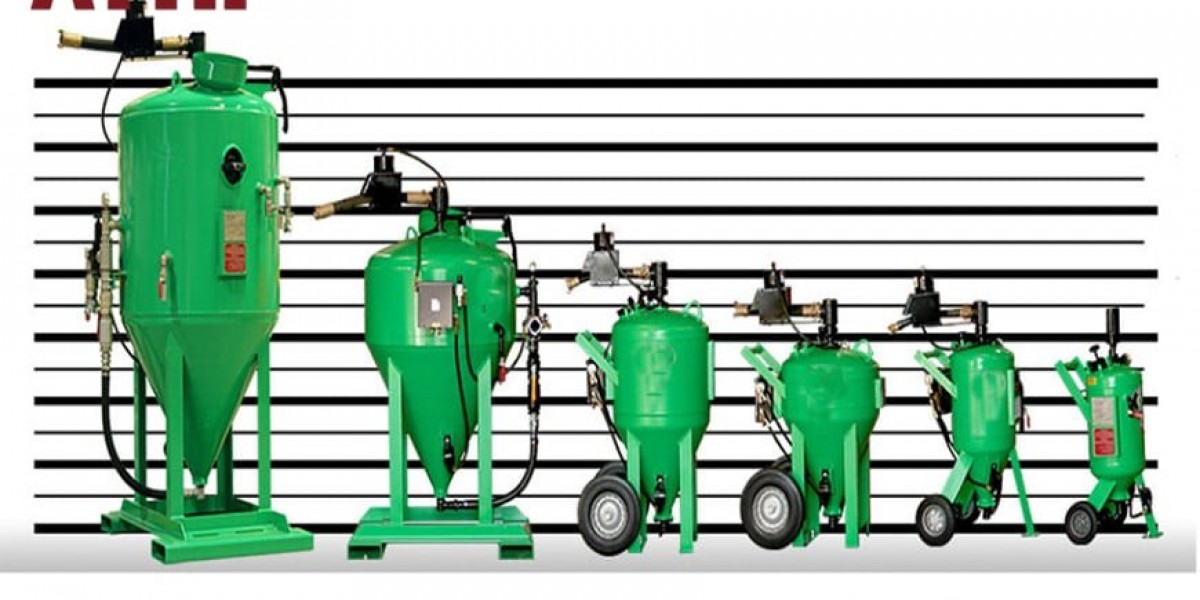

When selecting a sandblasting machine, you'll need to evaluate five critical components that determine operational efficiency. Consider your abrasive media requirements, pressure system specifications (50-130 PSI range), recovery system effectiveness, cabinet construction durability, and dust collection capacity. Match your compressed air supply (CFM) to nozzle specifications, and verify the cabinet size accommodates your largest workpieces. Understanding these technical aspects will position you to make an informed investment decisio

To maximize your return on investment, we're including complimentary operator training sessions with each purchase during this promotional period. You'll learn proper technique, troubleshooting procedures, and preventive maintenance practices from certified instructors. This value-added service guarantees your team can operate the equipment safely and efficiently from day on

To maximize your return on investment, we're including complimentary operator training sessions with each purchase during this promotional period. You'll learn proper technique, troubleshooting procedures, and preventive maintenance practices from certified instructors. This value-added service guarantees your team can operate the equipment safely and efficiently from day onThe choice ultimately depends on factors like surface hardness, contamination level, and desired finish quality. Consider testing small areas first to ensure compatibility with your specific applicatio

Consider the blast cabinet's construction material and design. Steel cabinets with reinforced wear plates in high-impact areas offer superior durability compared to aluminum alternatives. The cabinet should feature adequate lighting, clear visibility through impact-resistant viewing windows, and ergonomic operator access. Confirm the cabinet size accommodates your largest workpieces while maintaining proper working distance for ideal blast pattern