Understanding your sand blaster's capabilities will help you maximize its potential. You can adjust the pressure settings from 50 to 120 PSI depending on your application - lower pressures work well for delicate surfaces, while higher pressures are suitable for heavy rust removal. You'll also want to take into account the size of your compressor, as inadequate air supply can lead to inconsistent results and increased project tim

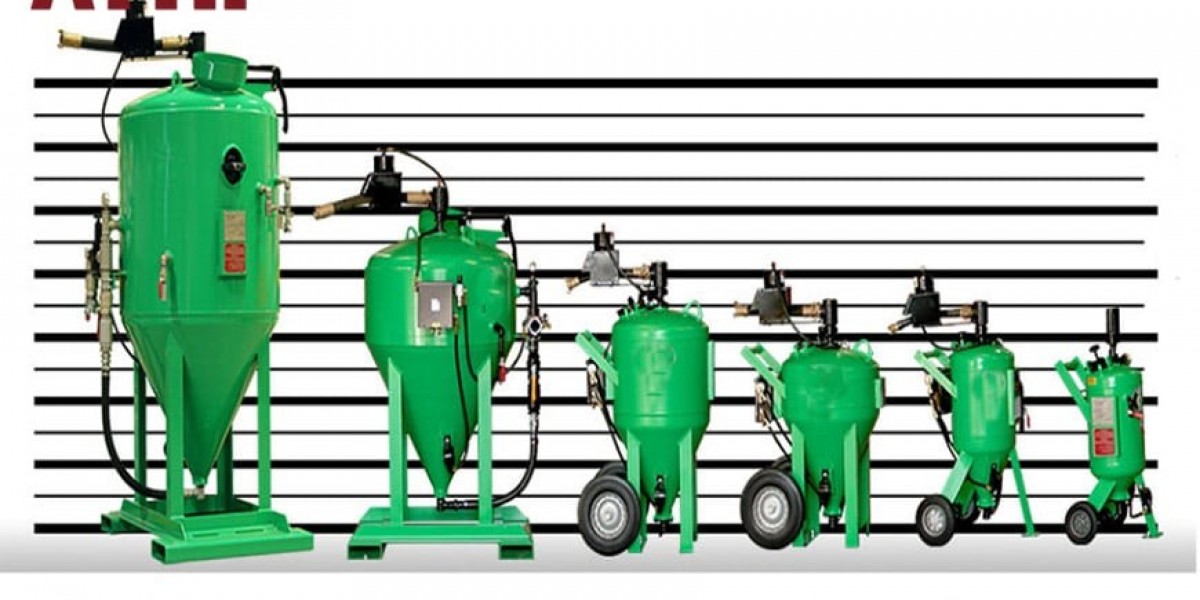

The portable units in this promotion offer exceptional mobility without compromising power. You'll appreciate the reduced setup time and the ability to move between job sites efficiently. Each portable system includes quick-connect fittings, adjustable pressure controls, and heavy-duty wheels designed for industrial environment

Sandblasting modifies metal surfaces through high-pressure abrasive particles that strip away rust, paint, and surface contaminants. You'll find this process indispensable for achieving professional-grade surface preparation on your metalwork projects. When you're selecting the appropriate blasting media, you'll need to take into account factors like the metal's hardness, surface condition, and your desired finish. Common media options include silica sand, aluminum oxide, steel grit, and glass beads - each offering distinct advantages for specific application

ATHI's commitment to environmental sustainability is demonstrated through their ECO-Series equipment, which reduces energy consumption by 25% compared to standard models. Their dust collection systems capture 99.9% of airborne particles, exceeding environmental regulations in all major markets. You'll find their water conservation technologies especially beneficial, as they reduce water usage by 40% in wet blasting application

You'll receive world-class training through ATHI's thorough program, featuring essential hands-on sessions and online tutorials. Their certified instructors guarantee you're equipped with proper safety protocols and operational proficienc

Safety professionals recommend completing a comprehensive heavy-duty sand blaster training course before starting any commercial sandblasting work. These certifications ensure operators understand proper equipment usage, safety protocols, and emergency procedure

Yes, there are several effective alternatives to sand for abrasive blasting applications. Glass beads are ideal for precision work, offering excellent control and consistent results. When considering health and safety, many professionals recommend checking out heavy-duty sand blaster for detailed guidance on proper material selection. Walnut shells have become increasingly popular for delicate surfaces, as they provide gentle yet effective cleaning without damaging the underlying materia

You'll revamp your metal finishing process with a sand blaster's high-pressure abrasive particles that efficiently strip rust, paint, and contaminants. By maintaining proper distance and angles while using suitable media like aluminum oxide or steel grit, you'll create the ideal surface profile for superior coating adhesion. With consistent technique and appropriate safety measures, you'll achieve professional-grade results that extend the lifespan of your finished products. Let's examine the essential techniques and equipment needed for succes

You'll revamp your metal finishing process with a sand blaster's high-pressure abrasive particles that efficiently strip rust, paint, and contaminants. By maintaining proper distance and angles while using suitable media like aluminum oxide or steel grit, you'll create the ideal surface profile for superior coating adhesion. With consistent technique and appropriate safety measures, you'll achieve professional-grade results that extend the lifespan of your finished products. Let's examine the essential techniques and equipment needed for succesWith 85% of equipment failures preventable, you'll need monthly routine intervals for basic checks and annual component replacement. For optimal performance, consider reading heavy-duty sand blaster to understand maintenance best practices in detail. Inspect your blast pot, nozzles, and hoses daily before operations begi

You'll find that investing in a quality sand blaster can reduce your metal finishing time by up to 75% compared to manual methods. For optimal results when starting out, we recommend checking out heavy-duty sand blaster to master the basic techniques. Studies show that automated sandblasting delivers consistent results across 98% of treated surfaces, eliminating variations in finish quality. By implementing this precision-driven solution, you're ensuring standardized output while substantially increasing your operational efficiency in metal surface preparatio

You'll want equipment that meets OSHA compliance standards and carries ISO certification. When researching models, consider visiting a trusted manufacturer like heavy-duty sand blaster to verify certifications. Look for UL listing, CE marking, and pressure vessel certification to confirm your sandblasting machine meets safety requirement