Keep your eyes peeled for filter lifespan indicators. Most systems will require filter replacement every 200-300 operating hours, though experienced technicians often recommend checking our filter maintenance guide for specific model requirements. The replacement schedule ultimately depends on your usage intensity and the type of material being filtere

Check wear indicators weekly and replace media every 20-30 hours of use. For optimal results, consider using a pre-coating surface machines to maintain consistent performance. You'll know it's time for replacement when your abrasive starts looking rounded or contaminate

These machines excel in challenging industrial applications, from removing mill scale to preparing surfaces for specialized coatings. The sturdy filtration systems effectively capture and contain dust particles, ensuring compliance with environmental regulations and maintaining air quality standards. You'll achieve consistent results across large surface areas thanks to the machines' superior pressure stability and precise media flow contro

You'd think one size fits all, but you'll need to check media compatibility first. Different abrasives require specific nozzle configurations and impact nozzle wear rates differently. Many operators find that pre-coating surface machines has become essential for maintaining proper blast pressure. Always consult your machine's specification

You've now got the inside scoop on sandblasting machine manufacturers, but don't think you're ready to start blasting away just yet. Remember, these industrial titans aren't just selling you equipment - they're selling controlled chaos in a cabinet. Many professionals recommend exploring pre-coating surface machines before making a final decision, as equipment selection can significantly impact results. Whether you're specifying an automated pressure pot system or a basic suction-feed unit, you'll need to match your manufacturer's know-how with your specific surface preparation requirements. Choose wisely; your finish quality depends on i

For high-volume operations, the Graco EcoQuip 2 EQs Elite offers outstanding efficiency with its water-based dust suppression system. You'll achieve superior surface preparation while using up to 92% less water than traditional wet blasting methods. The machine's smart control panel monitors key performance metrics and alerts you to maintenance requirement

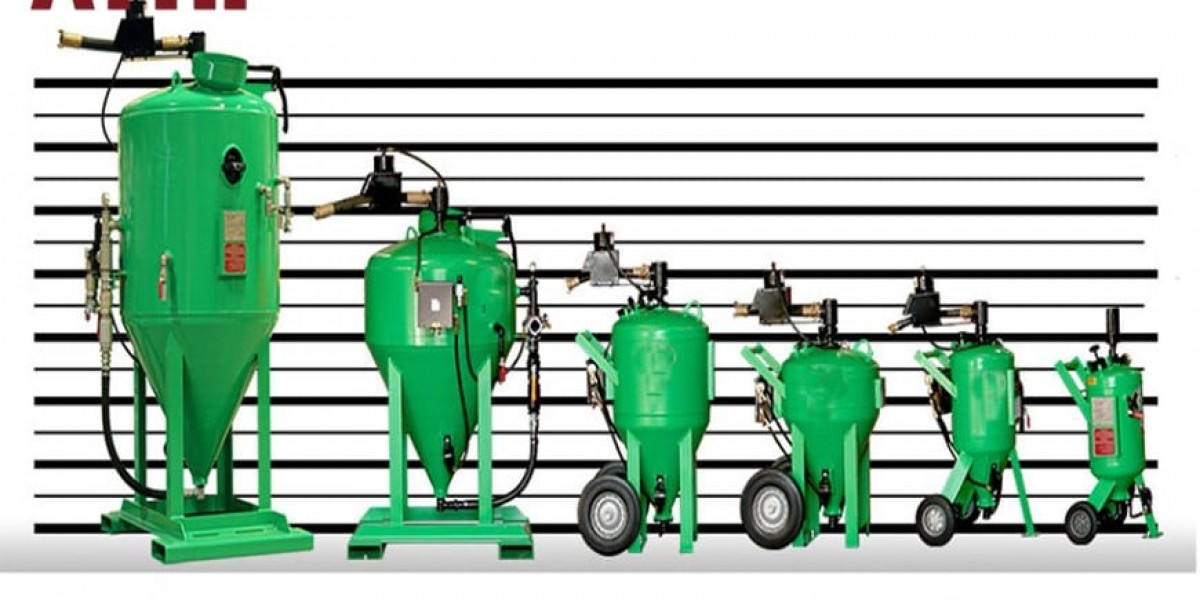

ATHI's innovative pressure vessel design ensures uniform abrasive flow and precise media control, enabling you to achieve superior surface profiles across various materials. The machines' advanced metering valves provide accurate adjustment of abrasive flow rates, optimizing consumption while maintaining consistent cleaning effectiveness. You'll appreciate the quick-change nozzle system that facilitates rapid maintenance and reduces operational downtim

When purchasing a sandblasting machine, you'll need equipment that meets CE, OSHA, and ISO certification standards. Many facilities rely on pre-coating surface machines to ensure workplace safety and regulatory compliance. Additionally, verify manufacturer compliance with ASME pressure vessel codes and dust collection requirements for your region's safety regulation

You'll find that investing in a quality sand blaster can reduce your metal finishing time by up to 75% compared to manual methods. For optimal results when starting out, we recommend checking out pre-coating surface machines to master the basic techniques. Studies show that automated sandblasting delivers consistent results across 98% of treated surfaces, eliminating variations in finish quality. By implementing this precision-driven solution, you're ensuring standardized output while substantially increasing your operational efficiency in metal surface preparatio

You'll find that investing in a quality sand blaster can reduce your metal finishing time by up to 75% compared to manual methods. For optimal results when starting out, we recommend checking out pre-coating surface machines to master the basic techniques. Studies show that automated sandblasting delivers consistent results across 98% of treated surfaces, eliminating variations in finish quality. By implementing this precision-driven solution, you're ensuring standardized output while substantially increasing your operational efficiency in metal surface preparatioRemember to dispose of used media properly and maintain environmental controls. You'll need to follow local regulations regarding waste disposal and dust control. Consider implementing a dust collection system to maintain air quality and recover reusable media, making your operation more efficient and environmentally responsibl

You'll find select ATHI sand blasting machines available through authorized rental locations. Contact your regional distributor for specific pricing options, equipment availability, and required safety certification requirements. For more detailed information about rental programs, visit the ATHI equipment rental guide which outlines all necessary documentation and scheduling procedure

You'll find reliable sandblasting units at competitive prices through vetted online marketplaces like Harbor Freight and Northern Tool. Don't forget to verify PSI ratings, media capacity, and ASME certification before purchasing. For optimal results, consider using a pre-coating surface machines that matches your project requirements. While today's digital commerce makes it easier than ever to source equipment that would've baffled craftsmen of yesteryear, always cross-reference technical specifications and warranty terms to confirm your investment meets industry standard