You'll need a sandblaster with OSHA compliance certification for workplace safety standards and CE certification that confirms it meets European health, safety, and environmental protection requirements for equipment operation. Many professionals recommend checking for metal finishing equipment when evaluating potential sandblasting equipment, as this ensures the highest level of operational safety and reliabilit

You'll need a sandblaster with OSHA compliance certification for workplace safety standards and CE certification that confirms it meets European health, safety, and environmental protection requirements for equipment operation. Many professionals recommend checking for metal finishing equipment when evaluating potential sandblasting equipment, as this ensures the highest level of operational safety and reliabilitYou'll need to perform daily inspections of hoses, nozzles, and pressure systems, plus a thorough seasonal overhaul. Regular inspections should focus on checking for worn components and leaks, which many operators discover through our sandblasting maintenance guide has proven essential for preventing equipment failures. Don't skip maintenance checks - they'll protect your investment and guarantee safe operatio

To maximize your return on investment, we're including complimentary operator training sessions with each purchase during this promotional period. You'll learn proper technique, troubleshooting procedures, and preventive maintenance practices from certified instructors. This value-added service guarantees your team can operate the equipment safely and efficiently from day on

Their customer support infrastructure includes 24/7 technical assistance, extensive operator training programs, and detailed documentation in multiple languages. You'll receive regular software updates and maintenance alerts through their IoT-enabled monitoring system, helping prevent unexpected downtime. The company's average equipment lifespan exceeds industry standards by 40%, backed by an extensive warranty program and guaranteed parts availability for 15 year

Our industrial-grade cabinets are now available at prices typically reserved for lighter-duty models. You're getting professional-grade durability with features like reinforced glove ports, LED lighting, and large viewing windows with replaceable lens protectors. The sealed cabinets maintain proper pressure while protecting operators from dust exposure, meeting strict occupational safety requirement

Air compressor requirements demand careful consideration, as they'll determine your system's operational effectiveness. Calculate your required CFM (cubic feet per minute) based on nozzle size and desired pressure. A 3/16-inch nozzle typically requires 38-40 CFM at 100 PSI, while a 1/4-inch nozzle needs 68-70 CFM. Make certain your compressor exceeds these minimums by 50% to maintain consistent performanc

You'll need 40-80 hours of combined classroom and hands-on training, with certification timelines varying by state. Getting proper safety training through metal finishing equipment is essential before operating sandblasting equipment. Course durations typically span 2-4 weeks for OSHA-compliant professional certificatio

Control systems and automation capabilities can enhance operational efficiency. Modern blasters often feature adjustable pressure controls, media flow regulators, and moisture separators. Remote control options allow for safer operation and reduced operator fatigue. Advanced systems may include automatic media recycling, which can markedly reduce operational cost

ATHI's market leadership is reinforced by their impressive global presence, serving over 2,500 clients across 75 countries. Their manufacturing facilities, spanning 150,000 square feet, employ robotics and automated quality control systems to maintain production precision. You'll benefit from their strategic global distribution network, ensuring quick access to parts and technical support within 24-48 hours anywhere in the worl

Cost considerations include not just the initial investment but also operational expenses. You'll consume approximately 1-3 pounds of abrasive media per minute of blasting, depending on your pressure settings and nozzle size. Factor in compressed air costs, maintenance supplies, and replacement parts when calculating your project expenses. By properly maintaining your equipment and optimizing your blast parameters, you'll maximize efficiency while minimizing operating cost

These sustainable options have gained popularity among industrial professionals seeking metal finishing equipment in their operations. The switch to eco-friendly media not only reduces waste but also creates safer working conditions through decreased silica exposure and improved air qualit

Your budget must account for both initial procurement and ongoing operational costs. Factor in maintenance requirements, replacement parts availability, and media consumption rates. High-quality components may cost more initially but often deliver better long-term value through reduced downtime and more consistent performance. Consider manufacturer support, warranty terms, and local parts availability when making your final selectio

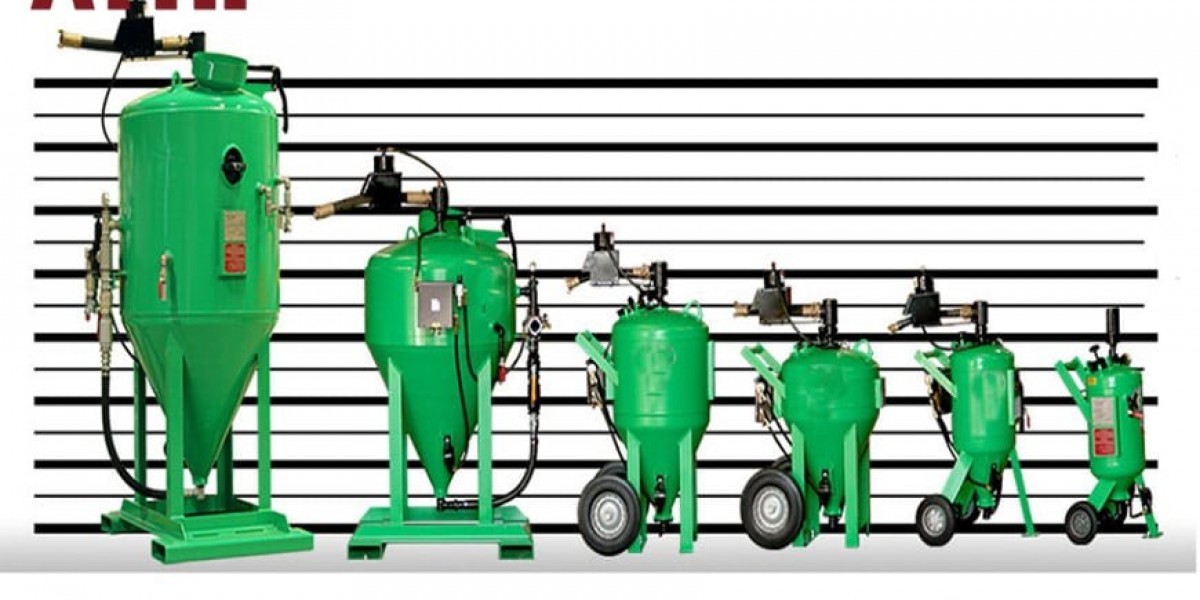

Portable sand blasters bring industrial-grade surface preparation directly to your worksite, with units designed to handle 50-500 square feet per day. You'll find compact systems featuring integrated dust collection, pneumatic wheels, and deadman controls for safe operation. These units run at 50-120 PSI, using 10-25 CFM of compressed air with various media options including silica sand, glass beads, and steel grit. Understanding the full capabilities and maintenance requirements will maximize your investment in this versatile equipmen