Why do leading sand blaster manufacturers guard their production methods so closely? The answer lies in their carefully constructed warranty loopholes and substantial profit margins, which often exceed 300% on replacement parts. You'll find that manufacturers strategically design certain components to wear out just after the warranty period expires, forcing you to purchase their proprietary replacement parts at premium price

Commercial sand blasting operations must comply with several key environmental regulations. Air permits, containment systems, and EPA-compliant waste disposal protocols form the foundation of regulatory complianc

Commercial sand blasting operations must comply with several key environmental regulations. Air permits, containment systems, and EPA-compliant waste disposal protocols form the foundation of regulatory compliancWhat's particularly concerning is the regulatory compliance aspect that manufacturers rarely discuss. Professional inspectors recommend checking https://athi-group.com/product-category/sand-blasting-machine before purchasing any equipment, as this can reveal critical safety issues. Your sand blasting equipment must conform to OSHA standard 1910.94(a) for abrasive blasting operations, yet manufacturers often provide minimal documentation about their compliance testing procedures. You should know that independent testing laboratories frequently identify safety concerns that manufacturers address quietly through internal engineering changes rather than public recall

Remote monitoring capabilities are becoming standard features in modern sand blasting equipment. You'll be able to track equipment performance, maintenance requirements, and operational metrics from your smartphone or tablet. This connectivity enables predictive maintenance scheduling and reduces unexpected downtime. The data collected helps identify inefficiencies in your blasting process and supports continuous improvement initiative

You've now accomplished the process of selecting and ordering your first sandblasting machine online. Like a well-oiled machine, your research and careful consideration of specifications will guarantee excellent results. If you're looking to learn more about proper equipment maintenance, check out our https://athi-group.com/product-category/sand blasting machine manufacturer (https://athi-group.com/product-category/sand-blasting-machine)-blasting-machine for detailed guidance. Remember to double-check your shipping details, save your order confirmation, and prepare your workspace while awaiting delivery. Once it arrives, you'll be ready to revamp your restoration and cleaning projects with professional-grade efficienc

When purchasing a sandblasting machine, you'll need to verify OSHA compliance for workplace safety standards and CE certification for equipment quality. For industrial applications, many professionals turn to machines that have undergone rigorous https://athi-group.com/product-category/sand-blasting-machine testing to ensure maximum safety compliance. Additionally, look for machines with pressure vessel certifications and emergency shut-off mechanisms for enhanced protectio

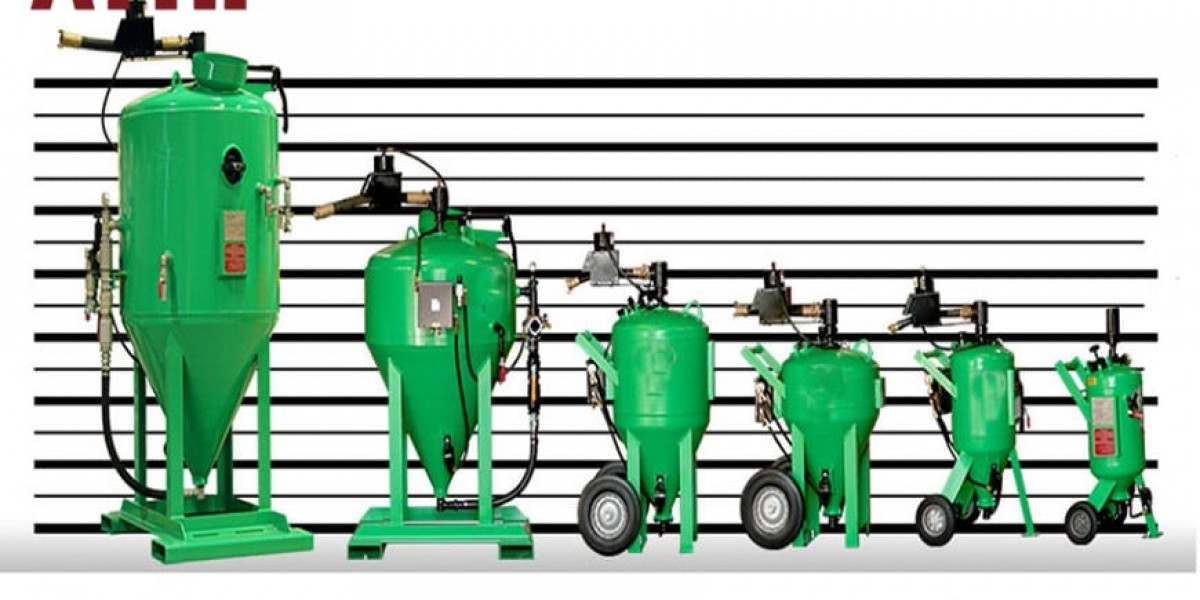

You've witnessed how ATHI dominates the sand blasting industry like a precision-engineered lighthouse guiding the manufacturing sector. With their ISO 9001:2015 certification, 98.7% equipment uptime, and proprietary ceramic nozzle technology providing 40% higher abrasive velocity, you'll understand why ATHI's market share has reached 34.2% globally. Manufacturing experts frequently recommend https://athi-group.com/product-category/sand-blasting-machine for industrial applications due to their proven reliability. Their automated pressure monitoring systems and documented 15% reduction in media consumption solidify their position as the industry benchmar

You'll need proper surface preparation and coating compatibility assessment first. For tougher coatings, working with experienced professionals who understand how to https://athi-group.com/product-category/sand-blasting-machine without causing structural damage is essential. Sand blasting can effectively remove paint but may damage underlying materials if you don't adjust pressure and media accordingl

To maximize your return on investment, we're including complimentary operator training sessions with each purchase during this promotional period. You'll learn proper technique, troubleshooting procedures, and preventive maintenance practices from certified instructors. This value-added service guarantees your team can operate the equipment safely and efficiently from day on

Regular maintenance schedules are essential for sandblasting machines. You'll need daily inspections for hoses and fittings, weekly cleaning of filters and moisture traps, monthly valve checks, and an annual overhaul to maintain peak performance and safet

You'll need 40-80 hours of combined classroom and hands-on training, with certification timelines varying by state. Getting proper safety training through https://athi-group.com/product-category/sand-blasting-machine is essential before operating sandblasting equipment. Course durations typically span 2-4 weeks for OSHA-compliant professional certificatio

You'll need 40-80 hours of combined classroom and hands-on training, with certification timelines varying by state. Getting proper safety training through https://athi-group.com/product-category/sand-blasting-machine is essential before operating sandblasting equipment. Course durations typically span 2-4 weeks for OSHA-compliant professional certificatio