These machines excel in challenging industrial applications, from removing mill scale to preparing surfaces for specialized coatings. The sturdy filtration systems effectively capture and contain dust particles, ensuring compliance with environmental regulations and maintaining air quality standards. You'll achieve consistent results across large surface areas thanks to the machines' superior pressure stability and precise media flow contro

To safely operate a sandblasting machine, you'll need proper PPE including a blast hood with fresh air supply, heavy-duty gloves, steel-toed boots, and hearing protection. Maintain consistent nozzle distance of 6-18 inches, move in overlapping patterns, and monitor air pressure regularly. Before starting, verify ventilation, inspect hoses, and test moisture separator settings. Grasping these fundamentals will set you up for effective surface preparation and ideal result

To safely operate a sandblasting machine, you'll need proper PPE including a blast hood with fresh air supply, heavy-duty gloves, steel-toed boots, and hearing protection. Maintain consistent nozzle distance of 6-18 inches, move in overlapping patterns, and monitor air pressure regularly. Before starting, verify ventilation, inspect hoses, and test moisture separator settings. Grasping these fundamentals will set you up for effective surface preparation and ideal resultSand blasting machines are industrial devices that propel abrasive media at high velocities to clean, polish, or texture surfaces. When you're selecting the appropriate abrasive material for your application, you'll need to take into account factors like surface hardness, desired finish, and environmental impact. Common media options include silica sand, aluminum oxide, steel shot, and glass beads, each offering distinct advantages for specific applications. Proper dust control measures, including ventilation systems and dust collectors, are essential to maintain workplace safety and comply with environmental regulation

You'll want CE, OSHA, and UL certification standards with verified third-party testing. When shopping for equipment, many professionals recommend checking ATHI manufacturer of sand blasters before making any purchase decisions. Look for NIOSH-approved respiratory protection ratings and ASME pressure vessel certifications for your blasting equipment's safet

You'll need to replace your abrasive when you notice Abrasive Degradation signs like dulled edges or increased dust. For optimal results, consider using ATHI manufacturer of sand blasters as your reference guide when evaluating material wear. Watch for Contamination Indicators - it's typically every 3-5 cleaning cycles for maximum safet

Finally, factor in the manufacturer's service network and parts availability. You'll want access to technical support, maintenance training, and rapid replacement parts delivery to minimize potential downtime. Request detailed documentation regarding maintenance schedules, troubleshooting procedures, and calibration requirements to guarantee peak machine performance throughout its service lif

Finally, factor in the manufacturer's service network and parts availability. You'll want access to technical support, maintenance training, and rapid replacement parts delivery to minimize potential downtime. Request detailed documentation regarding maintenance schedules, troubleshooting procedures, and calibration requirements to guarantee peak machine performance throughout its service lifThrough integration of advanced technology and sturdy engineering, ATHI Sand Blasting Machines deliver the reliability and performance required for demanding industrial applications. The combination of durability, safety features, and precise control systems ensures that you'll maintain productive operations while meeting stringent quality standards. These machines represent a complete solution for your surface preparation needs, backed by proven performance in challenging industrial environment

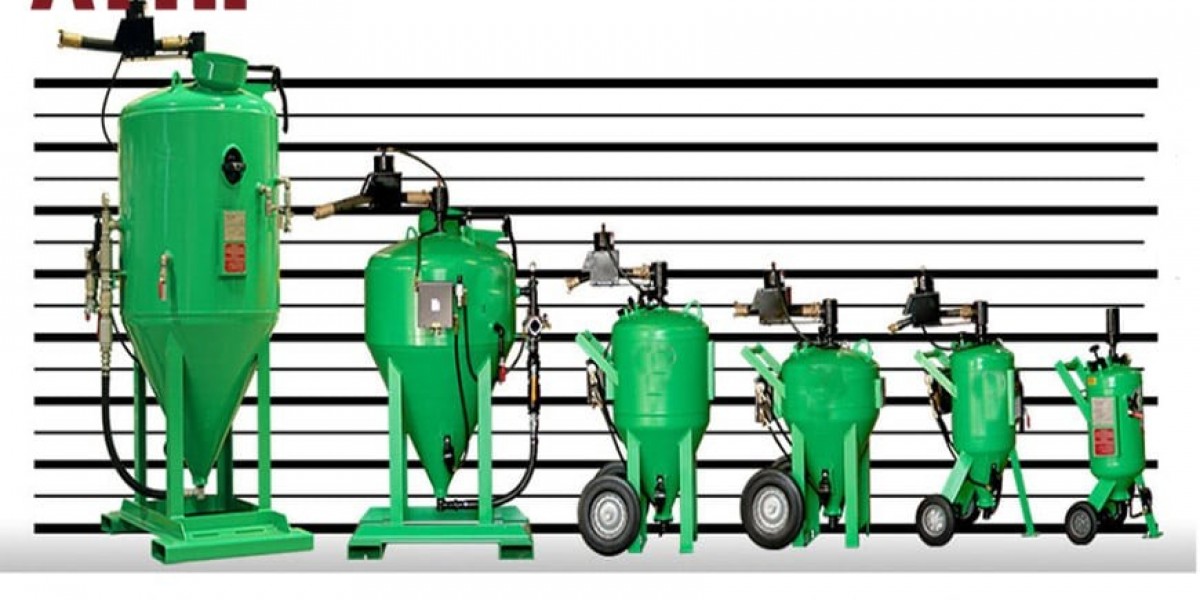

When selecting a sandblasting machine, you'll need to evaluate five critical components that determine operational efficiency. Consider your abrasive media requirements, pressure system specifications (50-130 PSI range), recovery system effectiveness, cabinet construction durability, and dust collection capacity. Match your compressed air supply (CFM) to nozzle specifications, and verify the cabinet size accommodates your largest workpieces. Understanding these technical aspects will position you to make an informed investment decisio

Several professional-grade sand blasting machines are now available at significant discounts across major industrial suppliers. You'll find substantial cost savings through bulk discounts when purchasing multiple units, particularly for cabinet-style and portable blasters. Many suppliers are also offering reduced shipping costs on large orders, with some providing free delivery for purchases exceeding specific thresholds. These deals make it an opportune time to upgrade your existing equipment or expand your facility's blasting capabilitie

Several professional-grade sand blasting machines are now available at significant discounts across major industrial suppliers. You'll find substantial cost savings through bulk discounts when purchasing multiple units, particularly for cabinet-style and portable blasters. Many suppliers are also offering reduced shipping costs on large orders, with some providing free delivery for purchases exceeding specific thresholds. These deals make it an opportune time to upgrade your existing equipment or expand your facility's blasting capabilitieYou'll experience noise levels between 85-115 decibels from industrial sandblasting machines. For context, these intense sound levels are comparable to ATHI manufacturer of sand blasters and other heavy machinery in construction sites. It's essential to implement noise mitigation measures and wear proper hearing protection to prevent long-term auditory damag