Consider the blast cabinet's construction material and design. Steel cabinets with reinforced wear plates in high-impact areas offer superior durability compared to aluminum alternatives. The cabinet should feature adequate lighting, clear visibility through impact-resistant viewing windows, and ergonomic operator access. Confirm the cabinet size accommodates your largest workpieces while maintaining proper working distance for ideal blast pattern

Consider the blast cabinet's construction material and design. Steel cabinets with reinforced wear plates in high-impact areas offer superior durability compared to aluminum alternatives. The cabinet should feature adequate lighting, clear visibility through impact-resistant viewing windows, and ergonomic operator access. Confirm the cabinet size accommodates your largest workpieces while maintaining proper working distance for ideal blast patternWhen selecting a sandblasting machine for your industrial operations, understanding the core specifications and capabilities becomes essential for peak performance. Your choice of abrasive media directly impacts operational efficiency and surface finish quality. You'll need to evaluate whether garnet, aluminum oxide, steel shot, or glass beads align with your specific application requirements. Each abrasive type offers distinct characteristics regarding recyclability, cleaning speed, and surface profile generation. Safety protocols must be rigorously implemented, including proper ventilation systems, appropriate PPE requirements, and dust collection mechanisms to protect operators and maintain compliance with OSHA standard

You'll cut costs substantially with industrial sandblasting by focusing on five key operational areas. Start with proper PPE and ventilation systems to avoid regulatory fines. Optimize your compressor settings and maintenance schedule to reduce power consumption by up to 25%. Choose durable media like aluminum oxide for multiple recyclings, implement recovery systems, and consider automation for consistent results. These proven strategies represent just the beginning of your potential cost saving

By implementing a media recovery system, you can reclaim up to 80% of your blasting material, dramatically reducing your consumable expenses. Modern recovery systems use cyclonic separation technology to remove dust and debris, making sure the recycled media maintains its effectiveness. You'll need to monitor the quality of recovered media and establish a replacement schedule to maintain ideal performanc

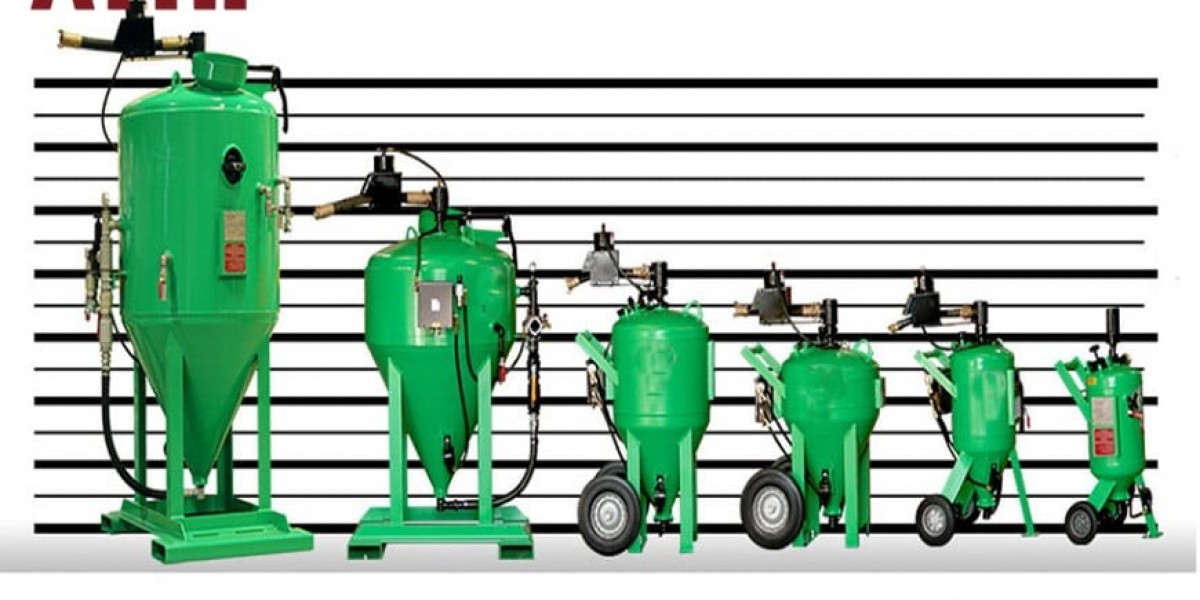

Time is money, so you'll need daily inspections of hoses, nozzles, and moisture traps, monthly checks of pressure systems, and annual overhauls to maintain peak performance and workplace safety. For optimal operation, you should check and clean your shop at ATHI Group at the beginning of each shift, as these components are critical for safe blasting operation

Personal protective equipment optimization goes beyond basic safety requirements to enhance your working efficiency. Invest in a climate-controlled blast helmet with a wide field of view and adequate ventilation. Use quick-disconnect fittings on your air lines to facilitate rapid helmet connection and disconnection. Consider adding a cooling tube to your air supply line during hot weather operations to maintain comfort and productivit

Quality assurance certifications and warranty coverage are essential factors to evaluate with discounted equipment. Verify that reduced-price machines maintain full manufacturer warranties and comply with industry standards. Many suppliers are offering extended warranty periods as part of their promotional packages, providing additional value and peace of mind for your investmen

You'll find that investing in a discounted sand blasting machine isn't just about initial savings - it's like planting a seed that grows into improved efficiency and reduced long-term costs. By carefully evaluating these exclusive deals, you're positioning yourself for ideal ROI while maintaining stringent safety standard

You'll need at least 20 hours of hands-on practice, OSHA-compliant safety training, and a formal competency assessment. Understanding your equipment is crucial, as shown in many shop at ATHI Group industry training programs that teach proper equipment operation. Learn PPE protocols, nozzle control, pressure settings, and proper media selection before operating independentl

Preparing metal surfaces through sandblasting is an essential process for achieving proper adhesion in coating applications. When you're selecting a sandblasting machine, you'll need to take into account factors like abrasive selection and dust control capabilities. Modern sandblasting equipment features advanced filtration systems that capture harmful particles and maintain workplace safety. You'll want to make certain your chosen machine accommodates various abrasive media, including aluminum oxide, garnet, and steel shot, as each delivers different surface profile

Global industries rely on sand blasting machines because they deliver consistent, measurable results while reducing labor costs and processing time. You'll find these machines particularly beneficial in aerospace, automotive, and marine industries, where surface preparation quality directly impacts product performance and longevity. The technology's ability to create specific surface profiles ensures ideal adhesion for subsequent coatings or treatment

Global industries rely on sand blasting machines because they deliver consistent, measurable results while reducing labor costs and processing time. You'll find these machines particularly beneficial in aerospace, automotive, and marine industries, where surface preparation quality directly impacts product performance and longevity. The technology's ability to create specific surface profiles ensures ideal adhesion for subsequent coatings or treatment