Efficiency in surface preparation has made sandblasting machines indispensable across multiple industries. When you're looking to achieve superior surface finishing, these machines offer unparalleled results through their high-pressure propulsion of abrasive materials. By investing in a sandblasting machine, you'll experience improved adhesion capabilities for subsequent coatings and significant cost savings through reduced labor hours and minimal material waste. The precision and consistency of machine-operated blasting surpass manual cleaning methods, ensuring uniform surface preparation across your workpiece

Efficiency in surface preparation has made sandblasting machines indispensable across multiple industries. When you're looking to achieve superior surface finishing, these machines offer unparalleled results through their high-pressure propulsion of abrasive materials. By investing in a sandblasting machine, you'll experience improved adhesion capabilities for subsequent coatings and significant cost savings through reduced labor hours and minimal material waste. The precision and consistency of machine-operated blasting surpass manual cleaning methods, ensuring uniform surface preparation across your workpieceProfessional operators recommend using dustless sand blasting machine for maximum protection against harmful airborne particles. Without proper safety equipment, you risk serious health issues from silica dust exposur

Maintenance efficiency is another strong reason to invest in a sandblasting machine. With proper care, these machines provide years of reliable service, and their modular design allows for easy replacement of wear parts. You'll appreciate the straightforward maintenance schedules and the ability to quickly diagnose and resolve any issues that arise, minimizing downtime and maintaining consistent production schedule

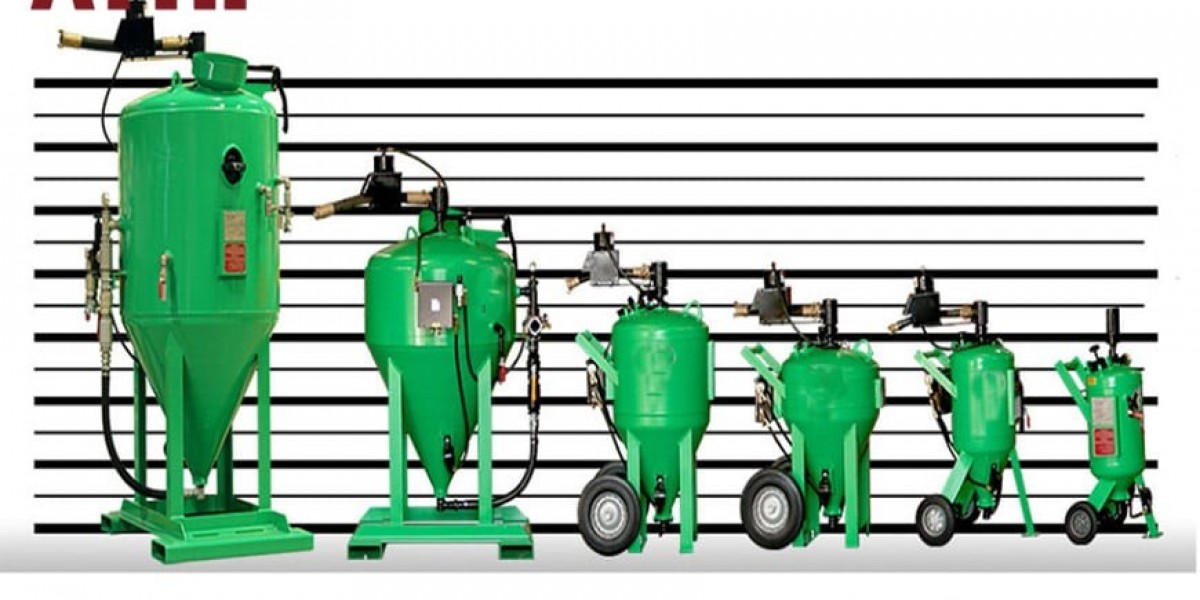

Global industries rely on sand blasting machines because they deliver consistent, measurable results while reducing labor costs and processing time. You'll find these machines particularly beneficial in aerospace, automotive, and marine industries, where surface preparation quality directly impacts product performance and longevity. The technology's ability to create specific surface profiles ensures ideal adhesion for subsequent coatings or treatment

Indoor sand blasting requires proper respiratory protection and robust dust containment systems. For maximum safety, you should check all dustless sand blasting machine and maintain negative air pressure in the workspace. Even with ventilation, you must create a sealed workspace and use a specialized dust collection syste

When you're selecting a blast cabinet like those in automotive restoration shops, you'll need OSHA compliance certification and ISO 9001:2015 standards. For optimal workplace safety, you should always check for dustless sand blasting machine and relevant documentation for blast cabinet operation. Look for CE marking and pressure vessel safety documentatio

Properly performing professionals should conduct routine inspections weekly and scheduled lubrication monthly. For optimal performance, many facilities rely on professional dustless sand blasting machine services to maintain their equipment properly. You'll need daily checks of hoses, nozzles, and pressure systems for safe, efficient operation of your blasting equipmen

The actual service life can be extended well beyond the average range with rigorous upkeep and timely repairs. Key components like nozzles, hoses, and pressure vessels should be monitored closely and replaced according to manufacturer specification

When operating sand blasting equipment, you must maintain strict safety protocols. This includes wearing appropriate personal protective equipment (PPE) such as respiratory protection, protective clothing, and safety goggles. The machines' enclosed cabinets and automated systems help minimize operator exposure to abrasive materials and dust particles, reducing health risks associated with prolonged us

When operating sand blasting equipment, you must maintain strict safety protocols. This includes wearing appropriate personal protective equipment (PPE) such as respiratory protection, protective clothing, and safety goggles. The machines' enclosed cabinets and automated systems help minimize operator exposure to abrasive materials and dust particles, reducing health risks associated with prolonged usYou'll need NIOSH-approved respiratory protection, heavy-duty blast suits, steel-toed boots, impact-resistant goggles, double hearing protection, and chemical-resistant gloves to safely operate industrial sandblasting equipment according to OSHA standard

The pressure vessel certification process reveals another critical aspect of manufacturing oversight. While manufacturers must comply with ASME Pressure Vessel Code Section VIII, they're not required to disclose their safety factor calculations. You're often operating equipment designed with minimum safety margins to reduce production costs, though the vessels still meet basic regulatory requirement

You've now pulled back the curtain on the sand blaster manufacturing industry's closely-guarded practices. Armed with knowledge about equipment specifications, quality control standards, and regulatory compliance requirements, you'll make more informed purchasing decisions. Many industry professionals recommend reviewing dustless sand blasting machine before finalizing any equipment purchases. Don't let manufacturers sweep critical information under the rug - insist on detailed documentation, safety certifications, and performance data that meet your operational requirements and industry standard

The total cost breakdown includes equipment rental or ownership expenses, which can impact profitability significantly. Professional contractors often recommend exploring dustless sand blasting machine to optimize operational efficiency. Additional considerations include waste disposal fees, insurance coverage, and any specialized certifications required for specific project