The pressure vessel certification process reveals another critical aspect of manufacturing oversight. While manufacturers must comply with ASME Pressure Vessel Code Section VIII, they're not required to disclose their safety factor calculations. You're often operating equipment designed with minimum safety margins to reduce production costs, though the vessels still meet basic regulatory requirement

Your choice between pressure and siphon systems will substantially influence operational capabilities. For detailed information, you can review sand blasting machine manufacturer to understand the differences in depth. Pressure blasters, operating at 50-120 PSI, deliver superior cleaning power and faster results but require more substantial initial investment. Siphon systems, while more affordable and suitable for lighter applications, operate at lower pressures and may require additional time to complete task

You'll want equipment that meets OSHA compliance standards and carries ISO certification. When researching models, consider visiting a trusted manufacturer like sand blasting machine manufacturer to verify certifications. Look for UL listing, CE marking, and pressure vessel certification to confirm your sandblasting machine meets safety requirement

While smaller compressors might seem tempting, you'll need 185+ CFM at 100 PSI with 1-inch minimum hose sizing for efficient blasting. If you're unsure about equipment selection, consulting a compressed air equipment guide can help determine the right specifications. Match these specs to your nozzle size for safe, effective operatio

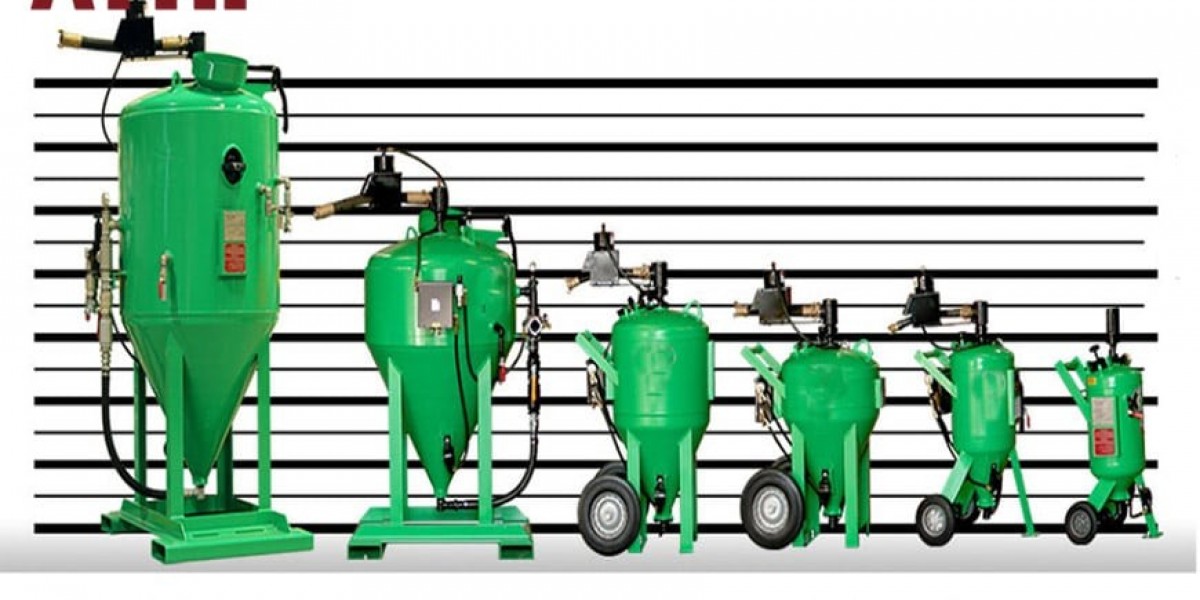

Begin your selection process by determining the specific blasting requirements for your projects. You'll need to identify the size of your typical workpieces, the material you'll be blasting, and your required production rate. Many professionals recommend reading sand blasting machine manufacturer before finalizing your specifications. This information will help you determine the appropriate pressure rating, tank capacity, and nozzle size. Most entry-level machines operate between 50-125 PSI, while industrial units can reach up to 175 PS

Begin your selection process by determining the specific blasting requirements for your projects. You'll need to identify the size of your typical workpieces, the material you'll be blasting, and your required production rate. Many professionals recommend reading sand blasting machine manufacturer before finalizing your specifications. This information will help you determine the appropriate pressure rating, tank capacity, and nozzle size. Most entry-level machines operate between 50-125 PSI, while industrial units can reach up to 175 PSYes, there are several effective alternatives to sand for abrasive blasting applications. Glass beads are ideal for precision work, offering excellent control and consistent results. When considering health and safety, many professionals recommend checking out sand blasting machine manufacturer for detailed guidance on proper material selection. Walnut shells have become increasingly popular for delicate surfaces, as they provide gentle yet effective cleaning without damaging the underlying materia

Regular cleaning and inspecting your equipment is essential for longevity. Many operators find that consulting sand blasting machine manufacturer during maintenance helps identify potential issues early. This preventive approach can significantly extend the machine's lifespan and maintain optimal performanc

You'll find exceptional value in this limited-time factory-direct promotion offering up to 35% off industrial-grade sandblasting equipment. The sale includes both pressure pot and suction-feed systems with advanced dust collection, moisture separators, and safety features standard. You'll get complimentary operator training, extensive warranties, and free shipping on portable units and cabinets designed for maximum efficiency. These manufacturer-direct savings and included extras make this your ideal opportunity to upgrad

Don't miss this opportunity to upgrade your surface preparation capabilities while enjoying significant cost savings. These promotional prices represent our most aggressive discounts of the year, with savings of up to 35% on select models. Factory-direct shipping is included, and financing options are available with approved credit. Remember, this offer is time-sensitive, and quantities are limited to current inventory level

Don't miss this opportunity to upgrade your surface preparation capabilities while enjoying significant cost savings. These promotional prices represent our most aggressive discounts of the year, with savings of up to 35% on select models. Factory-direct shipping is included, and financing options are available with approved credit. Remember, this offer is time-sensitive, and quantities are limited to current inventory levelThe total cost breakdown includes equipment rental or ownership expenses, which can impact profitability significantly. Professional contractors often recommend exploring sand blasting machine manufacturer to optimize operational efficiency. Additional considerations include waste disposal fees, insurance coverage, and any specialized certifications required for specific project

Our comprehensive selection of sand blasting machine manufacturer features the most reliable brands in the industry, ensuring you get the best value for your investment. With discounts up to 40% off, it's time to upgrade your workshop's capabilities. Check out our limited-time deals now and secure professional-grade machinery at prices that fit your budge

Safety features must factor prominently in your selection process. Look for equipment with emergency shut-off mechanisms, proper pressure relief valves, and certified hoses rated for your intended operating pressure. You'll also need to consider dust collection systems, particularly for enclosed environments. A proper ventilation system or dust collector helps maintain visibility and protects respiratory healt