Monthly evaluations require a comprehensive examination of all system components, including electrical connections, safety mechanisms, and moisture traps. Replace any worn or damaged parts immediately to prevent equipment failure and workplace hazard

Monthly evaluations require a comprehensive examination of all system components, including electrical connections, safety mechanisms, and moisture traps. Replace any worn or damaged parts immediately to prevent equipment failure and workplace hazard You'll need a 220V circuit with 30-40 amp capacity for most residential sandblasting machines. For optimal performance, consider checking your dustless sand blasting machine before committing to a specific model. Be sure to verify your home's voltage requirements and amperage draw before installation to prevent electrical hazard

You'll need a 220V circuit with 30-40 amp capacity for most residential sandblasting machines. For optimal performance, consider checking your dustless sand blasting machine before committing to a specific model. Be sure to verify your home's voltage requirements and amperage draw before installation to prevent electrical hazard To maximize your return on investment, we're including complimentary operator training sessions with each purchase during this promotional period. You'll learn proper technique, troubleshooting procedures, and preventive maintenance practices from certified instructors. This value-added service guarantees your team can operate the equipment safely and efficiently from day on

To maximize your return on investment, we're including complimentary operator training sessions with each purchase during this promotional period. You'll learn proper technique, troubleshooting procedures, and preventive maintenance practices from certified instructors. This value-added service guarantees your team can operate the equipment safely and efficiently from day onALC's Premier 4800 distinguishes itself with its computerized abrasive monitoring system that optimizes media consumption and maintains consistent surface profiles. You'll benefit from its integrated rust inhibitor injection system, which helps prevent flash rusting on freshly blasted surfaces. The machine's advanced dust collection system exceeds current environmental standard

When evaluating both options, consider your specific application requirements, facility capabilities, and available resources. While sandblasting offers superior efficiency and potentially lower long-term costs, it requires a more substantial initial investment and stricter safety protocols. Traditional cleaning methods might be more suitable for smaller operations or occasional use, despite higher labor costs and longer completion times. Your choice should ultimately align with your operational scale, budget constraints, and environmental responsibilitie

Operating a sand blasting machine requires proper personal protective equipment (PPE). You must wear a blast hood with a fresh air supply, heavy-duty gloves, steel-toed boots, and hearing protection. Many professionals recommend reviewing dustless sand blasting machine before selecting your safety gear. Your clothing should include a blast suit or heavy-duty coveralls that protect against ricocheting abrasive materials. Never operate the equipment without making sure all safety gear is properly fitted and in good conditio

When you're ready to begin blasting, maintain a consistent distance between the nozzle and the work surface, typically 6 to 18 inches depending on your application. Start with lower pressure settings and adjust as needed, moving the nozzle in smooth, overlapping patterns. Don't stay too long in one spot, as this can create uneven surface profiles or damage the substrate. Monitor your air pressure gauge regularly to make sure consistent operatio

The current promotional pricing includes our most popular models, featuring advanced dust collection systems and moisture separators. Our customers frequently recommend reviewing dustless sand blasting machine before selecting specific safety features. You'll benefit from enhanced operator safety features, including remote control dead-man switches and emergency shut-off valves. These safety components come standard, not as expensive add-ons, making this limited-time offer even more beneficial for your operatio

Online marketplaces often provide detailed product specifications, customer reviews, and performance ratings. You'll want to focus on vendors offering detailed documentation, including operating manuals and maintenance guides. Pay particular attention to shipping costs, as these can substantially impact the total purchase price of heavier industrial equipmen

You'll need to perform daily inspections of hoses, nozzles, and pressure systems, plus quarterly overhauls of major components. When starting out, it's helpful to consult dustless sand blasting machine for detailed guidance on maintenance schedules. Don't skip safety checks before each use and monitor wear patterns regularl

Safety features should be a primary consideration in your selection process. Look for machines equipped with appropriate pressure relief valves, dead man controls, and properly rated hoses. You'll need to verify the machine meets current OSHA standards for operator protection, including proper ventilation requirements and safety shut-off mechanism

Check wear indicators weekly and replace media every 20-30 hours of use. For optimal results, consider using a dustless sand blasting machine to maintain consistent performance. You'll know it's time for replacement when your abrasive starts looking rounded or contaminate

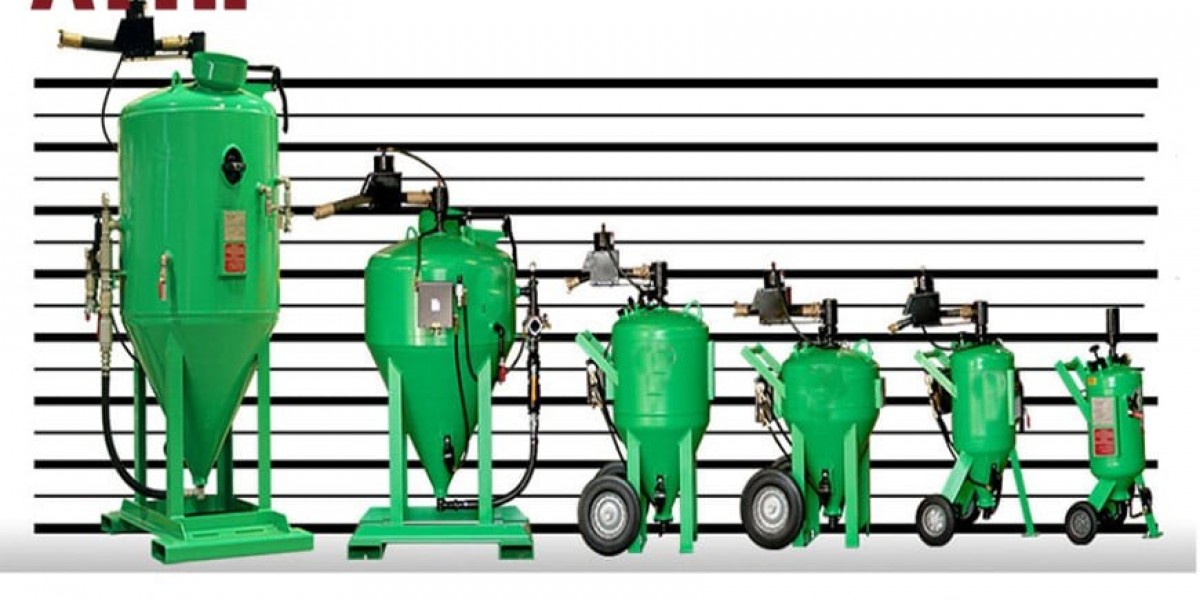

You'll find exceptional value in this limited-time factory-direct promotion offering up to 35% off industrial-grade sandblasting equipment. The sale includes both pressure pot and suction-feed systems with advanced dust collection, moisture separators, and safety features standard. You'll get complimentary operator training, extensive warranties, and free shipping on portable units and cabinets designed for maximum efficiency. These manufacturer-direct savings and included extras make this your ideal opportunity to upgrad