You'll need NIOSH-approved respiratory protection, heavy-duty blast suits, steel-toed boots, impact-resistant goggles, double hearing protection, and chemical-resistant gloves to safely operate industrial sandblasting equipment according to OSHA standard

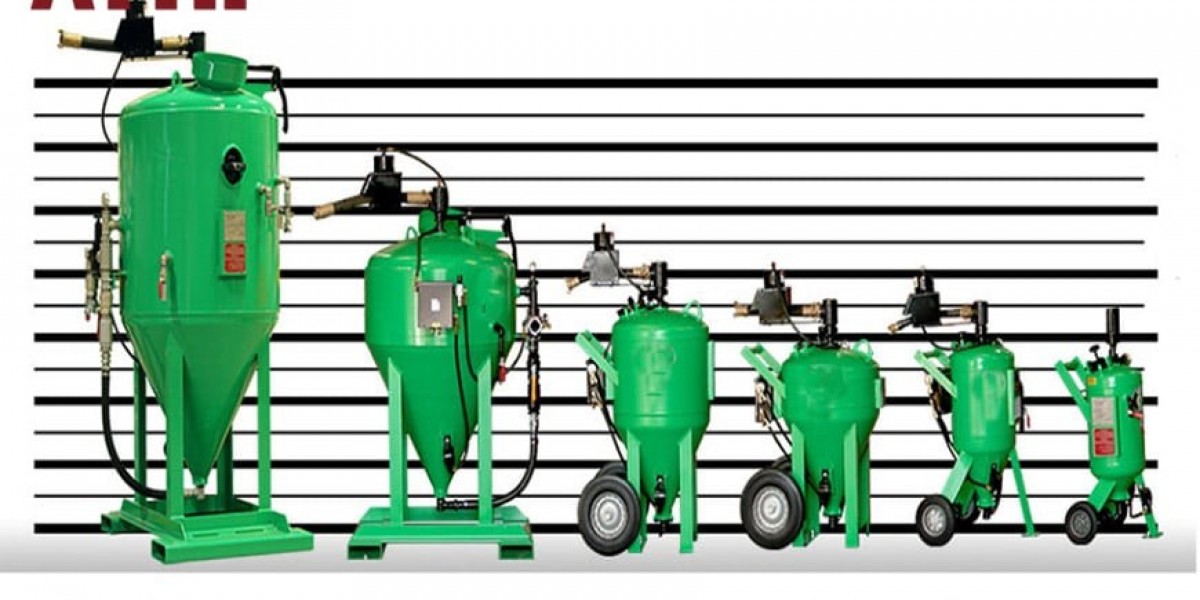

You'll need NIOSH-approved respiratory protection, heavy-duty blast suits, steel-toed boots, impact-resistant goggles, double hearing protection, and chemical-resistant gloves to safely operate industrial sandblasting equipment according to OSHA standardThe total cost breakdown includes equipment rental or ownership expenses, which can impact profitability significantly. Professional contractors often recommend exploring https://athi-group.com/product-category/sand-blasting-machine to optimize operational efficiency. Additional considerations include waste disposal fees, insurance coverage, and any specialized certifications required for specific project

Dust collection systems are non-negotiable for indoor blasting operations. You'll need to verify the dust collector's capacity matches your machine's size and usage patterns. Check that the filtration system meets current environmental regulations and can effectively capture the specific media you'll be using. Weigh whether you need additional ventilation equipment to maintain safe air quality in your workspac

You'll absolutely need a dust collection system for indoor blasting. It's essential for maintaining air quality, meeting OSHA requirements, and reducing long-term maintenance costs through proper particle containment. Professional contractors often recommend starting with a https://athi-group.com/product-category/sand-blasting-machine before investing in larger equipment to understand your specific need

When you've checked all these essential requirements, you'll be well-positioned to make a smart investment in your sandblasting equipment. Studies show that properly matched sandblasting machines reduce operational costs by up to 37% compared to mismatched systems. For detailed comparisons of cost-efficiency, you can review the https://athi-group.com/product-category/sand-blasting-machine from industry testing labs. Remember to prioritize safety features, verify equipment certifications, and make certain your chosen model aligns with your specific application requirements. Your thorough evaluation now will maximize efficiency and safety late

After completing your work, follow proper shutdown procedures. Depressurize the system completely before performing any maintenance. Clean all filters, empty the moisture separator, and inspect components for wear. Document any maintenance performed and schedule regular service intervals. Store your equipment in a dry location and cover exposed ends of hoses and nozzles to prevent contamination. By following these essential safety and operational guidelines, you'll maintain your equipment's efficiency while guaranteeing a safe working environmen

Preparing metal surfaces through sandblasting is an essential process for achieving proper adhesion in coating applications. When you're selecting a sandblasting machine, you'll need to take into account factors like abrasive selection and dust control capabilities. Modern sandblasting equipment features advanced filtration systems that capture harmful particles and maintain workplace safety. You'll want to make certain your chosen machine accommodates various abrasive media, including aluminum oxide, garnet, and steel shot, as each delivers different surface profile

The adaptability extends to crucial components, where you can find the right https://athi-group.com/product-category/sand-blasting-machine for your application, along with pressure control systems that ensure precise material removal. These modifications allow for optimal performance across different surface treatment

You've now pulled back the curtain on the sand blaster manufacturing industry's closely-guarded practices. Armed with knowledge about equipment specifications, quality control standards, and regulatory compliance requirements, you'll make more informed purchasing decisions. Many industry professionals recommend reviewing https://athi-group.com/product-category/sand-blasting-machine before finalizing any equipment purchases. Don't let manufacturers sweep critical information under the rug - insist on detailed documentation, safety certifications, and performance data that meet your operational requirements and industry standard

You've now pulled back the curtain on the sand blaster manufacturing industry's closely-guarded practices. Armed with knowledge about equipment specifications, quality control standards, and regulatory compliance requirements, you'll make more informed purchasing decisions. Many industry professionals recommend reviewing https://athi-group.com/product-category/sand-blasting-machine before finalizing any equipment purchases. Don't let manufacturers sweep critical information under the rug - insist on detailed documentation, safety certifications, and performance data that meet your operational requirements and industry standardLike a hungry beast, your sandblaster needs proper compressor sizing - typically 25-150 HP and 100-185 PSI. When selecting equipment, many operators find success with https://athi-group.com/product-category/sand-blasting-machine to ensure optimal performance levels. You'll also require 230/460V three-phase power compatibility for industrial-grade operation and safet

Like test-driving a car, you can rent sandblasting machines from equipment suppliers. Many businesses start by exploring their options through https://athi-group.com/product-category/sand-blasting-machine before making long-term decisions. This offers rental flexibility for short-term needs and project scalability while letting you evaluate performance before committing to purchas