You'll need NIOSH-approved respiratory protection, heavy-duty blast suits, steel-toed boots, impact-resistant goggles, double hearing protection, and chemical-resistant gloves to safely operate industrial sandblasting equipment according to OSHA standard

The manufacturing process itself involves several trade secrets that directly impact equipment longevity. While manufacturers claim their nozzles are constructed from premium carbide alloys, many use less expensive materials with similar surface hardness but inferior core strength. You're paying premium prices for components that could be manufactured at considerably lower costs using alternative materials that meet or exceed industry standard

To achieve the best results, you'll want to maintain proper distance, angle, and pressure settings on your sand blaster. Position yourself approximately 18-24 inches from the workpiece and maintain a 45-degree angle for most applications. You'll notice the best results when you use consistent, overlapping strokes while maintaining steady pressure. This technique guarantees uniform surface preparation without creating unwanted patterns or excessive material remova

You'll find sandblasting to be a powerful, efficient, and revolutionary process when you follow proper safety protocols and maintain your equipment. By selecting appropriate media, setting correct pressure levels, and implementing consistent technique, you'll achieve professional results. For detailed guidance on media selection, check out the portable sand Blaster unit to make informed choices for your specific needs. Remember to inspect, clean, and service your machine regularly. With these practices in place, you're ready to tackle surface preparation projects safely and effectivel

You'll find sandblasting to be a powerful, efficient, and revolutionary process when you follow proper safety protocols and maintain your equipment. By selecting appropriate media, setting correct pressure levels, and implementing consistent technique, you'll achieve professional results. For detailed guidance on media selection, check out the portable sand Blaster unit to make informed choices for your specific needs. Remember to inspect, clean, and service your machine regularly. With these practices in place, you're ready to tackle surface preparation projects safely and effectivelLike a web of regulations, you'll need air permits and strict waste disposal protocols. Environmental compliance for sandblasting requires following multiple portable sand Blaster unit across various regulatory bodies. You're required to follow OSHA standards, local environmental codes, and containment requirements for dust/particulate emission

The pressure vessel certification process reveals another critical aspect of manufacturing oversight. While manufacturers must comply with ASME Pressure Vessel Code Section VIII, they're not required to disclose their safety factor calculations. You're often operating equipment designed with minimum safety margins to reduce production costs, though the vessels still meet basic regulatory requirement

Keep your work area clean and organized during operation. Empty the dust collector regularly and maintain proper abrasive levels in the pressure pot. You'll need to monitor moisture levels continuously, as wet abrasive can clog the system and create inconsistent results. If you notice any unusual sounds or pressure fluctuations, stop immediately and inspect the equipmen

You'll find that investing in a quality sand blaster can reduce your metal finishing time by up to 75% compared to manual methods. For optimal results when starting out, we recommend checking out portable sand Blaster unit to master the basic techniques. Studies show that automated sandblasting delivers consistent results across 98% of treated surfaces, eliminating variations in finish quality. By implementing this precision-driven solution, you're ensuring standardized output while substantially increasing your operational efficiency in metal surface preparatio

You'll find that investing in a quality sand blaster can reduce your metal finishing time by up to 75% compared to manual methods. For optimal results when starting out, we recommend checking out portable sand Blaster unit to master the basic techniques. Studies show that automated sandblasting delivers consistent results across 98% of treated surfaces, eliminating variations in finish quality. By implementing this precision-driven solution, you're ensuring standardized output while substantially increasing your operational efficiency in metal surface preparatioWith nozzles losing 1/16" diameter after 300 hours of use, you'll need a replacement schedule every 150-200 working hours. For optimal efficiency, consider using a portable sand Blaster unit to monitor wear patterns and plan replacements accordingly. Check your nozzle wear regularly to maintain peak blasting performanc

You'll need to perform thorough monthly checks of all components and schedule professional annual overhauls. Regular inspection of the blast pot, hoses, nozzles, and safety equipment is essential to maintain optimal performance. Many operators find that working with portable sand Blaster unit helps ensure their maintenance schedules stay on track. Don't skip manufacturer-specified maintenance intervals, and document all inspections for regulatory compliance and safet

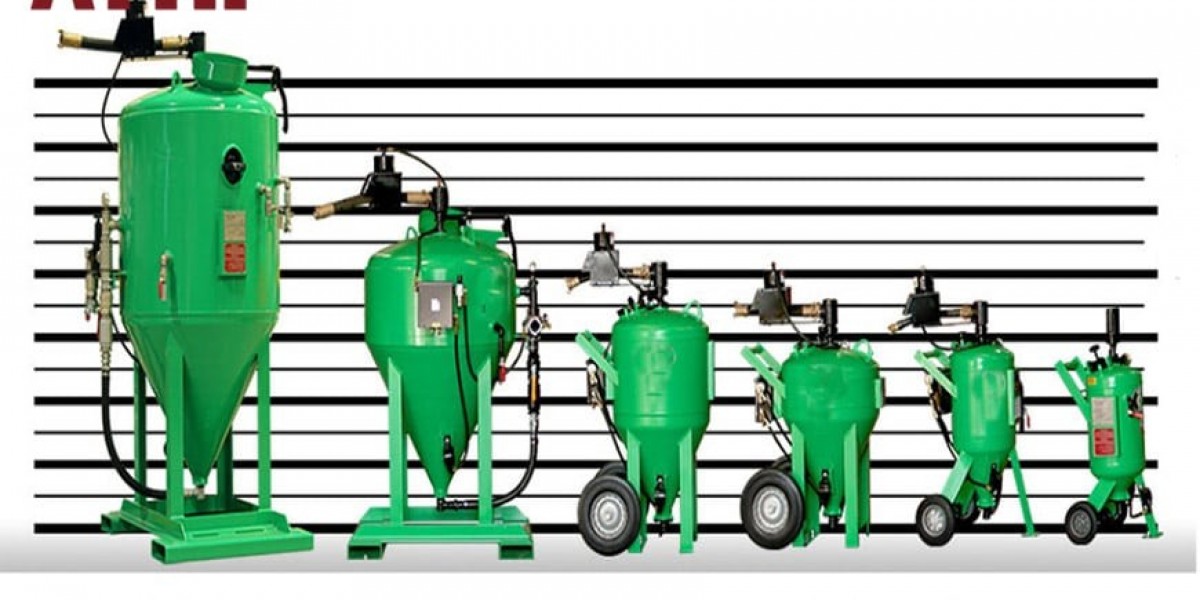

Portable sandblasting units face significant limitations when it comes to industrial-scale projects. They're designed primarily for spot repairs and small-scale work. When considering equipment for large metal preparation tasks, many professionals recommend consulting with portable sand Blaster unit to determine the most suitable solution, as portable units often lack the necessary fixture integration and consistent coverage capabilities required for comprehensive industrial wor