Safety should be your primary concern when operating portable blasting equipment. You must wear appropriate personal protective equipment, including a properly fitted respirator, heavy-duty gloves, and blast-resistant clothing. The blast pot should be equipped with a deadman control system, guaranteeing immediate shutdown if you release the trigger. You'll also need to maintain proper distance and angle during operation, typically 18-24 inches from the surface at a 45-90 degree angle for best result

Safety should be your primary concern when operating portable blasting equipment. You must wear appropriate personal protective equipment, including a properly fitted respirator, heavy-duty gloves, and blast-resistant clothing. The blast pot should be equipped with a deadman control system, guaranteeing immediate shutdown if you release the trigger. You'll also need to maintain proper distance and angle during operation, typically 18-24 inches from the surface at a 45-90 degree angle for best result The versatility of dustless blasting equipment allows you to work on a wide range of surfaces without causing damage. Many professionals recommend sand blasting machine for optimal results in various applications. Whether you're removing paint from delicate wood surfaces, cleaning industrial equipment, or preparing metal for coating, the adjustable pressure settings and various media options guarantee superior results. The water component acts as a natural cooling agent, preventing warping or heat damage that can occur with traditional dry blasting method

The versatility of dustless blasting equipment allows you to work on a wide range of surfaces without causing damage. Many professionals recommend sand blasting machine for optimal results in various applications. Whether you're removing paint from delicate wood surfaces, cleaning industrial equipment, or preparing metal for coating, the adjustable pressure settings and various media options guarantee superior results. The water component acts as a natural cooling agent, preventing warping or heat damage that can occur with traditional dry blasting method You'll need to replace your nozzle every 150-200 hours of use. Check your nozzle's wear pattern during monthly inspection intervals. For the best results, consider reviewing our sandblasting maintenance guide to understand the inspection process better. Replace immediately when the opening diameter increases by 1/16 inc

You'll need to replace your nozzle every 150-200 hours of use. Check your nozzle's wear pattern during monthly inspection intervals. For the best results, consider reviewing our sandblasting maintenance guide to understand the inspection process better. Replace immediately when the opening diameter increases by 1/16 incPersonal protective equipment optimization goes beyond basic safety requirements to enhance your working efficiency. Invest in a climate-controlled blast helmet with a wide field of view and adequate ventilation. Use quick-disconnect fittings on your air lines to facilitate rapid helmet connection and disconnection. Consider adding a cooling tube to your air supply line during hot weather operations to maintain comfort and productivit

Moisture control plays a critical role in preventing media clumping and maintaining smooth operation. Install a moisture separator in your air line, and position it as close to the blast pot as possible. You should drain the separator daily and consider adding a desiccant air dryer if you're working in particularly humid conditions. This investment will pay off by preventing costly downtime and maintaining consistent surface preparation qualit

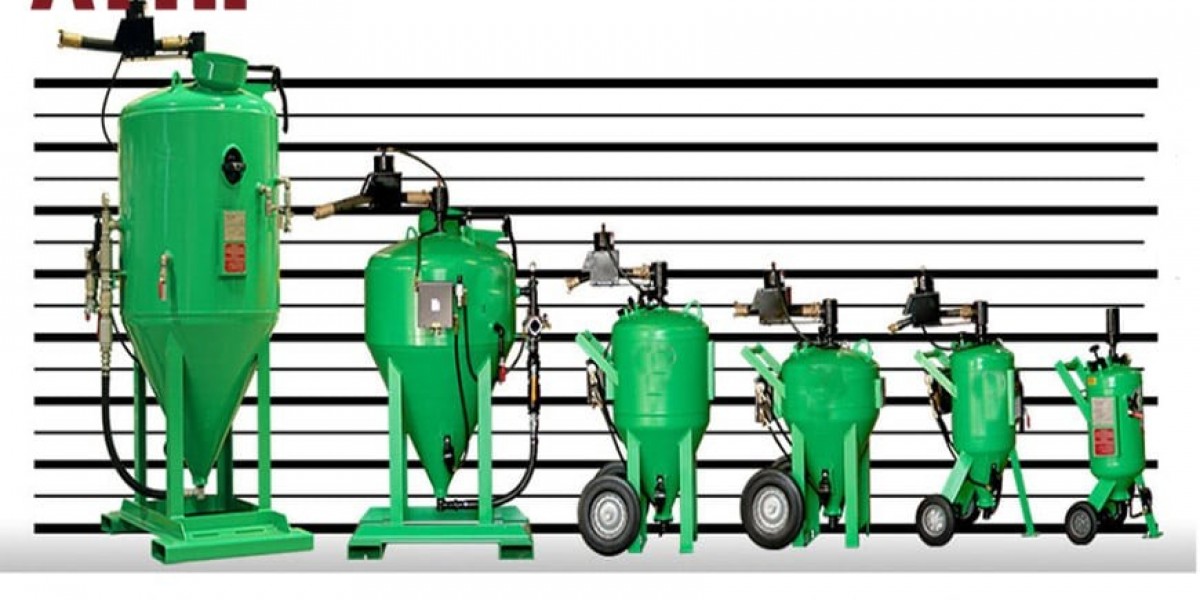

Portable sand blasters bring industrial-grade surface preparation directly to your worksite, with units designed to handle 50-500 square feet per day. You'll find compact systems featuring integrated dust collection, pneumatic wheels, and deadman controls for safe operation. These units run at 50-120 PSI, using 10-25 CFM of compressed air with various media options including silica sand, glass beads, and steel grit. Understanding the full capabilities and maintenance requirements will maximize your investment in this versatile equipmen

Embracing dustless sand blasting technology has revolutionized surface preparation and cleaning across multiple industries. When you're working with traditional sandblasting methods, you'll often encounter substantial dust pollution that can compromise both worker safety and environmental integrity. Dustless blasting systems incorporate water into the blast media, effectively suppressing up to 95% of airborne dust particles while maintaining superior surface preservation qualities. This innovative approach not only protects your workspace and surrounding areas but also guarantees environmental safety by preventing hazardous materials from becoming airborne contaminant

Safety features must factor prominently in your selection process. Look for equipment with emergency shut-off mechanisms, proper pressure relief valves, and certified hoses rated for your intended operating pressure. You'll also need to consider dust collection systems, particularly for enclosed environments. A proper ventilation system or dust collector helps maintain visibility and protects respiratory healt

Understanding your unit's limitations helps prevent operational issues. You'll achieve the best results when working within the manufacturer's recommended operating parameters. Most portable units are designed for projects requiring surface preparation of 50-500 square feet per day. The blast pattern typically ranges from 1-4 inches in width, depending on your nozzle size and operating pressure. You'll need to adjust these parameters based on the substrate material, desired profile depth, and production requirement

When the opening's diameter increases by 1/16 inch, it's time for a replacement. You can learn more about proper nozzle maintenance from sand blasting machine to ensure peak performance. Additionally, if you notice decreased pressure during operation, this indicates the nozzle needs immediate replacement to maintain effective blastin

Operating dustless blasting equipment contributes to improved workplace safety conditions. The reduction in airborne particles means you won't need to wear as much protective equipment, though proper safety gear remains essential. The improved visibility during operation allows for better control and more precise work, reducing the risk of accidents or mistakes during the blasting proces