You'll find the most competitive prices through major e-commerce platforms and industrial equipment marketplaces. Leading online retailers like Amazon, Northern Tool, and Harbor Freight frequently offer entry-level units ranging from $200 to $800, while professional-grade portable systems typically range from $1,000 to $3,000. When evaluating these options, verify the unit's CFM requirements match your available air compressor specification

You'll find the most competitive prices through major e-commerce platforms and industrial equipment marketplaces. Leading online retailers like Amazon, Northern Tool, and Harbor Freight frequently offer entry-level units ranging from $200 to $800, while professional-grade portable systems typically range from $1,000 to $3,000. When evaluating these options, verify the unit's CFM requirements match your available air compressor specificationYou'll receive world-class training through ATHI's thorough program, featuring essential hands-on sessions and online tutorials. Their certified instructors guarantee you're equipped with proper safety protocols and operational proficienc

When the opening's diameter increases by 1/16 inch, it's time for a replacement. You can learn more about proper nozzle maintenance from reliable sand blaster machine to ensure peak performance. Additionally, if you notice decreased pressure during operation, this indicates the nozzle needs immediate replacement to maintain effective blastin

When the opening's diameter increases by 1/16 inch, it's time for a replacement. You can learn more about proper nozzle maintenance from reliable sand blaster machine to ensure peak performance. Additionally, if you notice decreased pressure during operation, this indicates the nozzle needs immediate replacement to maintain effective blastinCustomers appreciate that ATHI offers comprehensive support, including reliable sand blaster machine which enhances operator confidence and machine performance. The combination of theoretical knowledge and practical experience ensures users can safely maximize their equipment's potentia

Professional operators recommend using reliable sand blaster machine for maximum protection against harmful airborne particles. Without proper safety equipment, you risk serious health issues from silica dust exposur

For optimal warranty coverage, make sure to check the latest warranty terms on our reliable sand blaster machine before operating your equipment. The warranty period begins from the date of purchase and requires proper maintenance record

ATHI Sand Blaster Manufacturer stands as a leading producer of industrial surface preparation equipment, specializing in automated and manual sandblasting solutions since 1985. The company's commitment to stringent Quality Standards has earned them ISO 9001:2015 certification, ensuring consistent product excellence across their entire range. Their thorough Safety Protocols exceed industry requirements, incorporating advanced dust collection systems, emergency shutoffs, and user-protection mechanisms in every unit manufacture

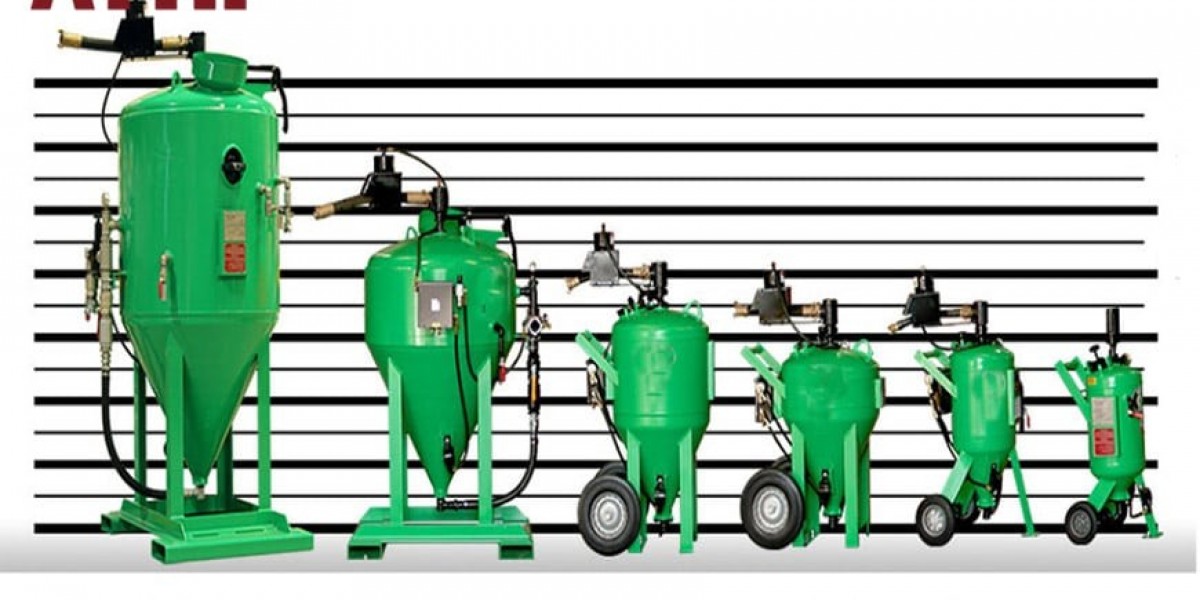

For peak performance and longevity, select machines with sturdy construction, featuring heavy-gauge steel hoppers and industrial-grade components. Prioritize units with readily available replacement parts and strong manufacturer support to minimize potential downtime and maintenance cost

You'll save substantially using recycled glass or plastic media, which can be reused multiple times. For detailed analysis and cost comparisons, many industry experts recommend checking industrial blasting media guides before making purchasing decisions. These materials are gentler on equipment, create less dust, and maintain effectiveness through several cleaning cycle

For industrial applications, you should check for reliable sand blaster machine which demonstrates compliance with European safety standards. Additional validations like pressure vessel certification and dust collection system compliance are also essential for safe operatio

You'll typically spend $150-250 per hour, factoring in your labor rates, equipment depreciation, media consumption, compressed air costs, and regulatory-mandated safety equipment maintenance and replacement schedule

You'll find reliable sandblasting machines through major e-commerce platforms like Amazon, Northern Tool, and Harbor Freight, with entry-level units ranging from $200-$800 and professional systems from $1,000-$3,000. Focus on vendors offering detailed documentation, customer reviews, and bundle deals that include essential PPE. Consider portable gravity-fed units operating at 60-125 PSI for best value in small-to-medium projects. Our thorough breakdown examines key specifications, safety features, and insider purchasing tip

You'll find reliable sandblasting machines through major e-commerce platforms like Amazon, Northern Tool, and Harbor Freight, with entry-level units ranging from $200-$800 and professional systems from $1,000-$3,000. Focus on vendors offering detailed documentation, customer reviews, and bundle deals that include essential PPE. Consider portable gravity-fed units operating at 60-125 PSI for best value in small-to-medium projects. Our thorough breakdown examines key specifications, safety features, and insider purchasing tipAir compressor requirements demand careful consideration, as they'll determine your system's operational effectiveness. Calculate your required CFM (cubic feet per minute) based on nozzle size and desired pressure. A 3/16-inch nozzle typically requires 38-40 CFM at 100 PSI, while a 1/4-inch nozzle needs 68-70 CFM. Make certain your compressor exceeds these minimums by 50% to maintain consistent performanc

The company's research and development department consistently introduces breakthrough technologies, with 15 patented innovations in the last decade alone. Their latest blast cabinet series incorporates AI-driven surface recognition, automatically adjusting blast parameters for ideal results across different materials. You'll achieve up to 30% reduction in media consumption through their advanced recycling systems, substantially lowering operational cost