You'll need to replace your blasting media when you notice reduced efficiency and surface quality. Check for media longevity by monitoring replacement indicators like worn, rounded shot and excessive dust productio

You must also consider your facility's infrastructure requirements. Shot blast machines need adequate power supply, compressed air systems (for air-powered units), and proper foundations to handle operational vibrations. The dust collection system must match your machine's capacity to maintain air quality and meet environmental regulations. Calculate your total investment by including installation costs, media consumption, energy usage, and replacement part expense

You must also consider your facility's infrastructure requirements. Shot blast machines need adequate power supply, compressed air systems (for air-powered units), and proper foundations to handle operational vibrations. The dust collection system must match your machine's capacity to maintain air quality and meet environmental regulations. Calculate your total investment by including installation costs, media consumption, energy usage, and replacement part expenseTo find the ideal shot blaster manufacturer, start with a systematic evaluation of technical capabilities, quality certifications, and production capacity. Manufacturers must demonstrate expertise through detailed documentation and proven track records in the industr

You'll get 10-15 years from well-maintained shot blasting equipment, though warranty periods typically range 1-3 years. Industrial depreciation rates suggest replacement planning after 7-8 years of heavy us

You'll need CE Certification for European standards compliance and ATEX Certification if you're operating in potentially explosive atmospheres. Also verify UL listing and OSHA compliance for your region's requirement

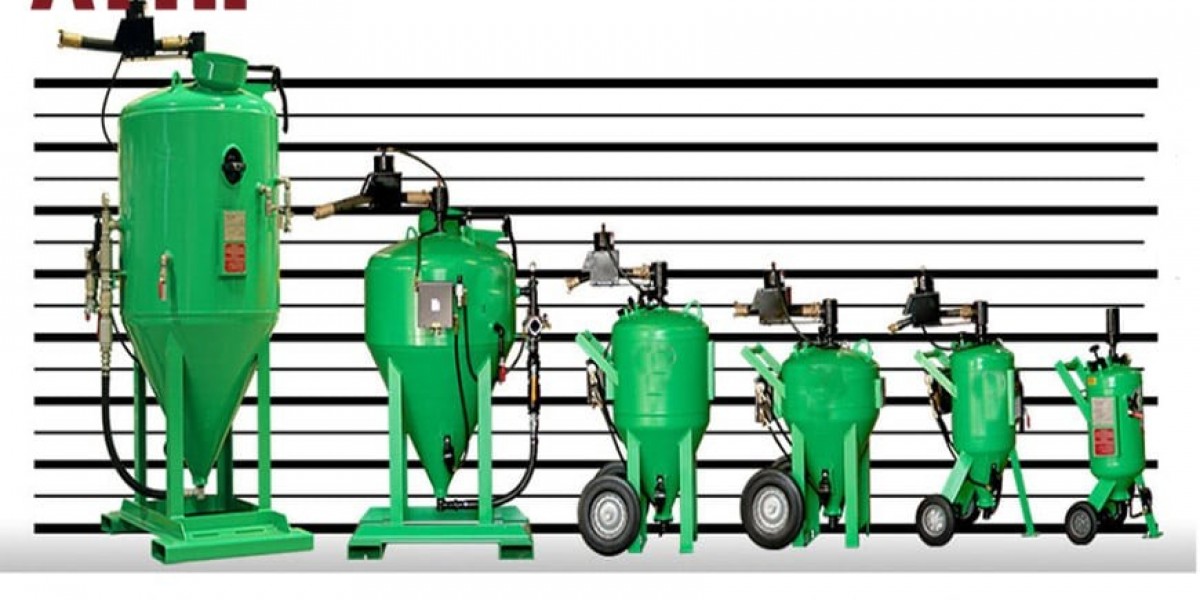

Shot blaster manufacturers design and produce industrial equipment that propels metallic abrasive media at high velocities to clean, strengthen, or prepare surfaces. When you're searching for the right manufacturer, you'll need to evaluate their equipment maintenance protocols and global sourcing capabilities. Leading manufacturers provide detailed maintenance schedules, readily available replacement parts, and thorough service documentation to guarantee your shot blasting equipment operates at peak efficiency. They'll also maintain resilient supply chains across multiple continents to guarantee consistent material quality and timely delivery of component

You've now gained thorough knowledge about shot blasting machines, from their mechanical principles to maintenance requirements. Whether you're selecting a wheel blasting system or an air-powered unit, remember that proper machine sizing, media selection, and blast pattern optimization are critical factors in your investment's success. For more detailed specifications, you can explore our industrial rust removal systems which provides comprehensive technical data and selection guides. Through careful analysis of your specific requirements and these technical parameters, you'll make an informed purchasing decision that maximizes operational efficienc

Built like a tank, your shot blasting machine will last 15-20 years with proper maintenance. You'll get 20,000-30,000 operating hours from a quality unit if you follow manufacturer's specifications and safety protocol

The material handling system's design must align with your workpiece characteristics, including size, weight, and geometry. You'll find various options such as wire mesh belt, roller conveyor, overhead rail, or tumblast systems. Each configuration presents specific advantages for different applications, and you must confirm the chosen system can safely handle your parts while maintaining consistent blast coverag

Advanced dust containment systems now capture 99.9% of airborne particles down to 0.3 microns, substantially improving workplace safety and environmental compliance. Many manufacturers are following the guidelines outlined in the industrial rust removal systems to ensure optimal dust control standards. You'll benefit from newly developed magnetic separation systems that recover up to 98% of reusable media while removing ferrous contamination. These innovations reduce waste and maximize your operational efficienc

Looking ahead, shot blasting technology continues to evolve with the development of hybrid systems that combine traditional media with alternative cleaning methods. You can expect to see increased integration with robotic systems, enabling precise treatment of complex geometries and consistent results across large production runs. These advancements, coupled with improved environmental controls and worker safety features, position shot blasting technology as an essential component in modern surface preparation processe

By selecting the right shot blasting machine, you'll convert your corroded, lackluster surfaces into mirror-like finishes that'll pass even the most stringent quality inspections. For optimal results, many manufacturers recommend consulting a detailed industrial rust removal systems before making your final equipment choice. Remember to thoroughly evaluate your operational requirements, material specifications, and compliance standards. When properly matched, your shot blasting system won't just clean - it'll revolutionize your surface preparation process while maintaining ISO 9001 and environmental regulation