You'll need to prevent hose freezing by keeping water lines heated. Experienced operators often consult resource for this article for detailed guidance on cold weather operation. Cold temperatures can increase slurry viscosity, so maintain your mix ratios carefully and monitor pressure settings during operatio

You'll need to prevent hose freezing by keeping water lines heated. Experienced operators often consult resource for this article for detailed guidance on cold weather operation. Cold temperatures can increase slurry viscosity, so maintain your mix ratios carefully and monitor pressure settings during operatioYou'll need a 220V circuit with 30-40 amp capacity for most residential sandblasting machines. For optimal performance, consider checking your resource for this article before committing to a specific model. Be sure to verify your home's voltage requirements and amperage draw before installation to prevent electrical hazard

You'll need to perform daily inspections of hoses, nozzles, and pressure systems, plus quarterly overhauls of major components. When starting out, it's helpful to consult resource for this article for detailed guidance on maintenance schedules. Don't skip safety checks before each use and monitor wear patterns regularl

The efficiency of sand blasting machines stems from their ability to process large surface areas quickly while maintaining quality standards. You'll achieve superior results through precise control over blast pressure, media flow, and working distance. These parameters can be adjusted to accommodate different material properties and surface requirements, making the process highly adaptable to various industrial application

Consider the blast cabinet's construction material and design. Steel cabinets with reinforced wear plates in high-impact areas offer superior durability compared to aluminum alternatives. The cabinet should feature adequate lighting, clear visibility through impact-resistant viewing windows, and ergonomic operator access. Confirm the cabinet size accommodates your largest workpieces while maintaining proper working distance for ideal blast pattern

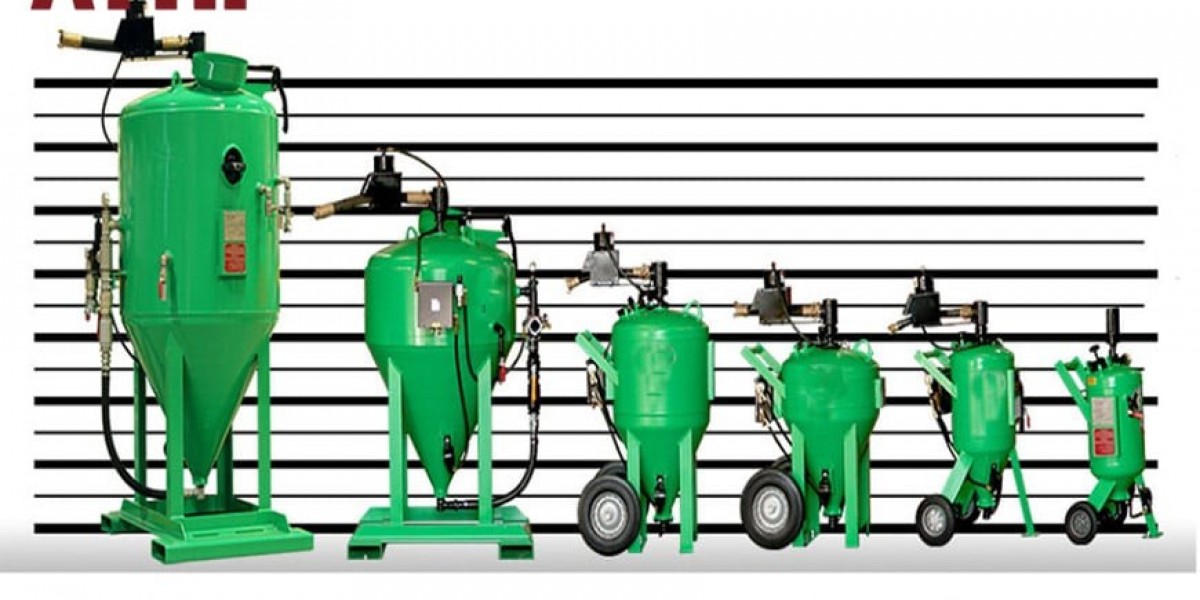

You'll find sand blasting machine supplier (resource for this article) blasting machines trusted globally for their unmatched surface preparation capabilities across diverse industries. These systems deliver precision control over abrasive media, pressure, and flow parameters to achieve ideal surface texturing, rust removal, and coating adhesion preparation. Through advanced dust control measures and automated monitoring, they guarantee consistent, high-quality results while maintaining safety standards. Explore how these versatile machines revolutionize surface treatment processes in manufacturing and maintenance application

Operating dustless blasting equipment contributes to improved workplace safety conditions. The reduction in airborne particles means you won't need to wear as much protective equipment, though proper safety gear remains essential. The improved visibility during operation allows for better control and more precise work, reducing the risk of accidents or mistakes during the blasting proces

Operating dustless blasting equipment contributes to improved workplace safety conditions. The reduction in airborne particles means you won't need to wear as much protective equipment, though proper safety gear remains essential. The improved visibility during operation allows for better control and more precise work, reducing the risk of accidents or mistakes during the blasting procesYou'll find reliable sandblasting units at competitive prices through vetted online marketplaces like Harbor Freight and Northern Tool. Don't forget to verify PSI ratings, media capacity, and ASME certification before purchasing. For optimal results, consider using a resource for this article that matches your project requirements. While today's digital commerce makes it easier than ever to source equipment that would've baffled craftsmen of yesteryear, always cross-reference technical specifications and warranty terms to confirm your investment meets industry standard

Quality assurance certifications and warranty coverage are essential factors to evaluate with discounted equipment. Verify that reduced-price machines maintain full manufacturer warranties and comply with industry standards. Many suppliers are offering extended warranty periods as part of their promotional packages, providing additional value and peace of mind for your investmen

When considering these promotional offers, you'll want to focus on machines that meet your specific application requirements while adhering to current safety standards. The latest models feature enhanced dust collection systems, improved pressure regulators, and reinforced seals that minimize media leakage. Many professionals recommend reviewing resource for this article before making a final selection. Many discounted units come equipped with advanced moisture separators and precise media flow controls, delivering consistent surface preparation result

Energy efficiency features are becoming increasingly common in newer models, potentially offsetting the initial investment through reduced operational costs. Look for machines with automatic shut-off features, optimized compressed air consumption, and efficient media recycling systems. These features can provide long-term savings beyond the initial purchase discoun

You should replace your nozzle when Wear Indicators show 1/16 inch expansion or according to your Maintenance Schedule, typically every 400-600 operating hours, to maintain safe, efficient blasting performanc

Like a web of regulations, you'll need air permits and strict waste disposal protocols. Environmental compliance for sandblasting requires following multiple resource for this article across various regulatory bodies. You're required to follow OSHA standards, local environmental codes, and containment requirements for dust/particulate emission