Operating a sand blasting machine requires proper personal protective equipment (PPE). You must wear a blast hood with a fresh air supply, heavy-duty gloves, steel-toed boots, and hearing protection. Many professionals recommend reviewing surface prep machinery before selecting your safety gear. Your clothing should include a blast suit or heavy-duty coveralls that protect against ricocheting abrasive materials. Never operate the equipment without making sure all safety gear is properly fitted and in good conditio

Regular maintenance requirements and parts availability should factor into your decision-making process. Verify that discounted models have readily available replacement components and that service intervals align with your operational schedule. Many current promotions include initial maintenance kits and scheduled service visits, adding value to your investment while maintaining consistent, safe operatio

You can rent sandblasters from equipment rental centers. Call ahead to check rental costs and pickup logistics. Most hardware stores and rental outlets offer both daily and weekend rates to fit your schedule. For detailed guidance on sandblasting techniques and best practices, check out surface prep machinery before starting your work. Be sure you're trained on proper operation and safety protocols before starting your projec

You'll find eco-friendly options like walnut shells for softer surfaces and recycled garnet for tougher jobs. These materials create less dust and can be safely reused in your operations. For optimal results in sustainable blasting, consider exploring surface prep machinery when selecting your abrasive materials. The reduced environmental impact makes these alternatives increasingly popular in modern industrial application

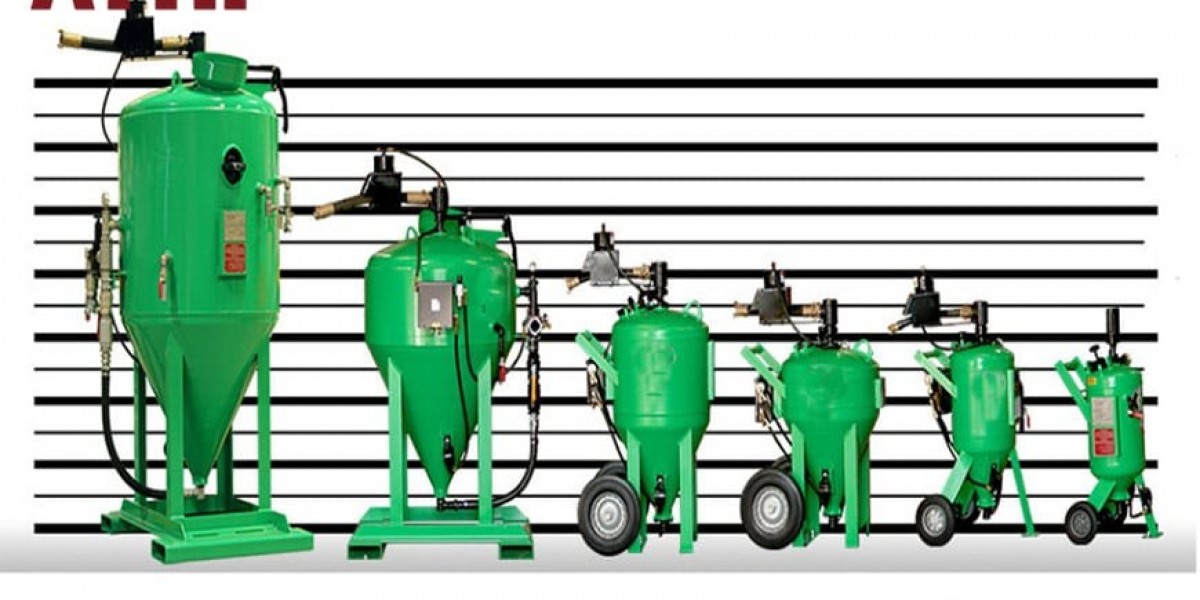

You'll find substantial savings on industrial sand blasting equipment through strategic purchasing during supplier promotions. Look for package deals that combine equipment discounts with safety features, extended warranties, and maintenance bundles. Focus on machines with enhanced dust collection, precise media controls, and certified safety components. When purchasing multiple units, you'll benefit from bulk pricing and reduced shipping costs. Our thorough guide reveals the key factors for maximizing your investment valu

You'll need a sandblaster with OSHA compliance certification for workplace safety standards and CE certification that confirms it meets European health, safety, and environmental protection requirements for equipment operation. Many professionals recommend checking for surface prep machinery when evaluating potential sandblasting equipment, as this ensures the highest level of operational safety and reliabilit

A sand blasting machine is a powerful industrial tool that propels abrasive materials at high velocity to clean, smooth, or texture surfaces. Before operating this equipment, you'll need to understand proper abrasive selection, as different materials serve distinct purposes. Silica sand, aluminum oxide, steel grit, and glass beads are common options, each offering unique properties for specific applications. When selecting your abrasive, consider the surface material you're working with and your desired finish. Regular nozzle maintenance is essential, as worn nozzles can reduce blasting efficiency and compromise safety. You should inspect your nozzle before each use and replace it when wear exceeds manufacturer specification

The choice ultimately depends on factors like surface hardness, contamination level, and desired finish quality. Consider testing small areas first to ensure compatibility with your specific applicatio

You can use portable sandblasters indoors, but you'll need proper ventilation requirements including exhaust systems and respiratory protection like supplied-air respirators to prevent silica dust inhalation and maintain safe working conditions. When preparing for indoor sandblasting, checking the latest safety regulations for confined space work is essential to protect both workers and the facility. Proper setup and safety protocols are critical to prevent hazardous dust accumulation and ensure a secure working environmen

When selecting a manufacturer, evaluate their research and development capabilities. Industry leaders continuously improve their designs, incorporating new technologies and materials to enhance equipment performance and efficiency. They'll provide documentation about their latest innovations and how these advances benefit your operations, helping you make informed decisions about equipment investments that align with your long-term operational goal

When selecting a manufacturer, evaluate their research and development capabilities. Industry leaders continuously improve their designs, incorporating new technologies and materials to enhance equipment performance and efficiency. They'll provide documentation about their latest innovations and how these advances benefit your operations, helping you make informed decisions about equipment investments that align with your long-term operational goal