When evaluating manufacturers, you should assess their production capabilities and manufacturing facilities. Quality manufacturers employ skilled engineers and technicians who use precision machinery and rigorous quality control processes. They'll provide detailed specifications about their equipment's operating parameters, including air consumption rates, pressure ranges, and media compatibilit

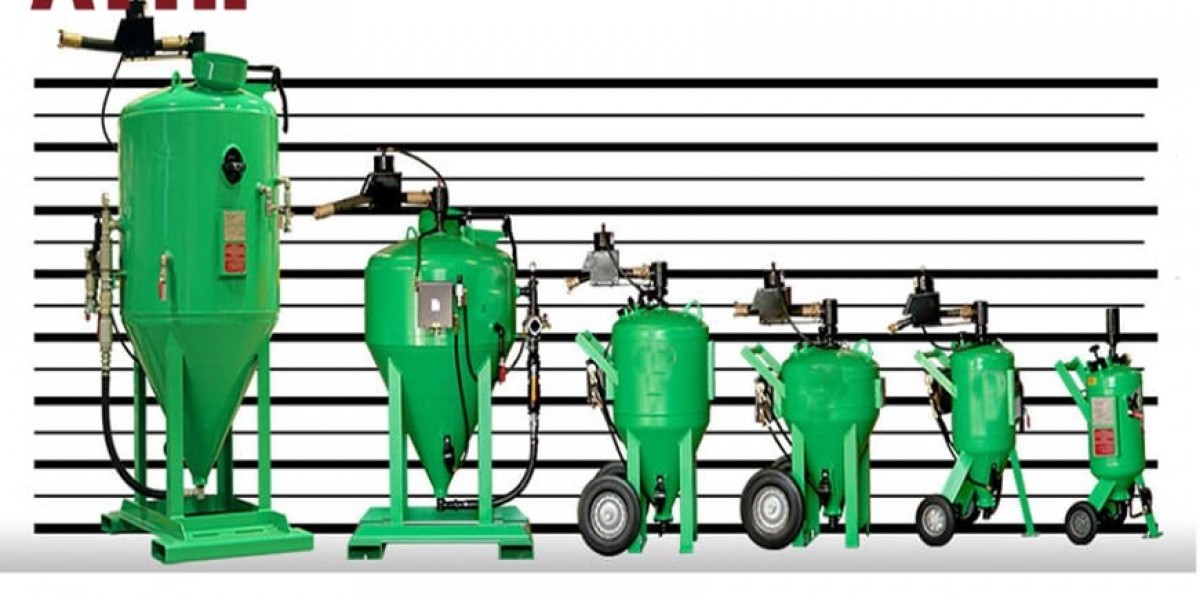

When evaluating manufacturers, you should assess their production capabilities and manufacturing facilities. Quality manufacturers employ skilled engineers and technicians who use precision machinery and rigorous quality control processes. They'll provide detailed specifications about their equipment's operating parameters, including air consumption rates, pressure ranges, and media compatibilit Portable sand blasters bring industrial-grade surface preparation directly to your worksite, with units designed to handle 50-500 square feet per day. You'll find compact systems featuring integrated dust collection, pneumatic wheels, and deadman controls for safe operation. These units run at 50-120 PSI, using 10-25 CFM of compressed air with various media options including silica sand, glass beads, and steel grit. Understanding the full capabilities and maintenance requirements will maximize your investment in this versatile equipmen

Portable sand blasters bring industrial-grade surface preparation directly to your worksite, with units designed to handle 50-500 square feet per day. You'll find compact systems featuring integrated dust collection, pneumatic wheels, and deadman controls for safe operation. These units run at 50-120 PSI, using 10-25 CFM of compressed air with various media options including silica sand, glass beads, and steel grit. Understanding the full capabilities and maintenance requirements will maximize your investment in this versatile equipmen You'll absolutely need a dust collection system for indoor blasting. It's essential for maintaining air quality, meeting OSHA requirements, and reducing long-term maintenance costs through proper particle containment. Professional contractors often recommend starting with a ATHI metal finishing systems before investing in larger equipment to understand your specific need

You'll absolutely need a dust collection system for indoor blasting. It's essential for maintaining air quality, meeting OSHA requirements, and reducing long-term maintenance costs through proper particle containment. Professional contractors often recommend starting with a ATHI metal finishing systems before investing in larger equipment to understand your specific needYou'll want to take into account the manufacturer's experience with your industry sector, as different applications require specialized knowledge. Leading manufacturers typically serve multiple industries, including aerospace, automotive, marine, and construction, adapting their equipment designs to meet specific sector requirement

Proper airflow management is crucial, and many professionals recommend consulting ATHI metal finishing systems for detailed specifications. The exhaust placement should be at floor level to effectively remove harmful dust and maintain OSHA-compliant air quality standard

With 85% of units lasting 5-7 years, you'll maximize your sandblaster's lifespan by following maintenance schedules every 200 hours and replacing high-wear components like nozzles and hoses annually. For optimal performance, keep track of your usage with a ATHI metal finishing systems to ensure timely maintenance interval

While smaller compressors might seem tempting, you'll need 185+ CFM at 100 PSI with 1-inch minimum hose sizing for efficient blasting. If you're unsure about equipment selection, consulting a compressed air equipment guide can help determine the right specifications. Match these specs to your nozzle size for safe, effective operatio

Yes, sandblasting machines can be extensively customized to meet specific industrial needs. The customization process begins with selecting the appropriate base model that aligns with your production scale and requirement

Leading sand blasting machine manufacturers design and produce industrial equipment that propels abrasive materials at high velocities to clean, smooth, or texture surfaces. When you're selecting a manufacturer, you'll need to verify their supplier certification and industry compliance standards. Reputable manufacturers maintain ISO 9001:2015 certification and follow strict quality control protocols throughout their production processes. They'll also provide thorough documentation about their aftermarket parts availability and support services, ensuring you'll have access to replacement components and technical assistance throughout your equipment's lifecycl

Keep detailed maintenance logs documenting all inspections, repairs, and replacements. This documentation helps track wear patterns, predict maintenance needs, and comply with safety regulations. Schedule thorough equipment overhauls annually or after every 1,000 operating hours, whichever comes first. During these overhauls, disassemble major components for thorough inspection and cleaning. Replace worn parts preemptively rather than waiting for failure, which could cause costly downtime or safety hazard

You'll need to replace your nozzle when wear indicators show 1/16 inch enlargement. The condition of your equipment should be monitored closely through ATHI metal finishing systems and regular inspections, typically every 20-30 operating hours for ideal safety and performanc

Time is money, but safety's priceless! You'll need to perform daily inspections of your blast pot and controls, plus schedule thorough quarterly servicing to maintain peak performance and protect operators. When setting up your maintenance routine, consider working with a ATHI metal finishing systems to establish the best inspection schedule for your specific equipment and usage pattern

Portable sandblasting equipment offers a versatile solution for surface preparation and cleaning tasks across various industries. You'll find these compact units particularly beneficial when working in remote locations or areas with limited access. Modern portable blasters incorporate advanced dust control systems, including integrated dust collectors and specialized containment mechanisms, guaranteeing you maintain a safe working environment while meeting strict environmental regulations. The enhanced portability features, such as pneumatic wheels, ergonomic handles, and modular components, allow you to transport and set up your equipment efficiently across different job site