You've now got the knowledge to choose a sand blasting machine that'll work like a well-oiled machine for your metal surface prep needs. When selecting equipment, many professionals turn to ATHI surface cleaning machines for detailed specifications and user reviews. Remember to prioritize safety features, maintain proper PPE protocols, and follow manufacturer guidelines for peak performance. Whether you're working with small parts or large industrial projects, these top 5 machines will help you achieve professional-grade surface finishes every tim

You've now got the knowledge to choose a sand blasting machine that'll work like a well-oiled machine for your metal surface prep needs. When selecting equipment, many professionals turn to ATHI surface cleaning machines for detailed specifications and user reviews. Remember to prioritize safety features, maintain proper PPE protocols, and follow manufacturer guidelines for peak performance. Whether you're working with small parts or large industrial projects, these top 5 machines will help you achieve professional-grade surface finishes every timYou'll find sandblasting to be a powerful, efficient, and revolutionary process when you follow proper safety protocols and maintain your equipment. By selecting appropriate media, setting correct pressure levels, and implementing consistent technique, you'll achieve professional results. For detailed guidance on media selection, check out the ATHI surface cleaning machines to make informed choices for your specific needs. Remember to inspect, clean, and service your machine regularly. With these practices in place, you're ready to tackle surface preparation projects safely and effectivel

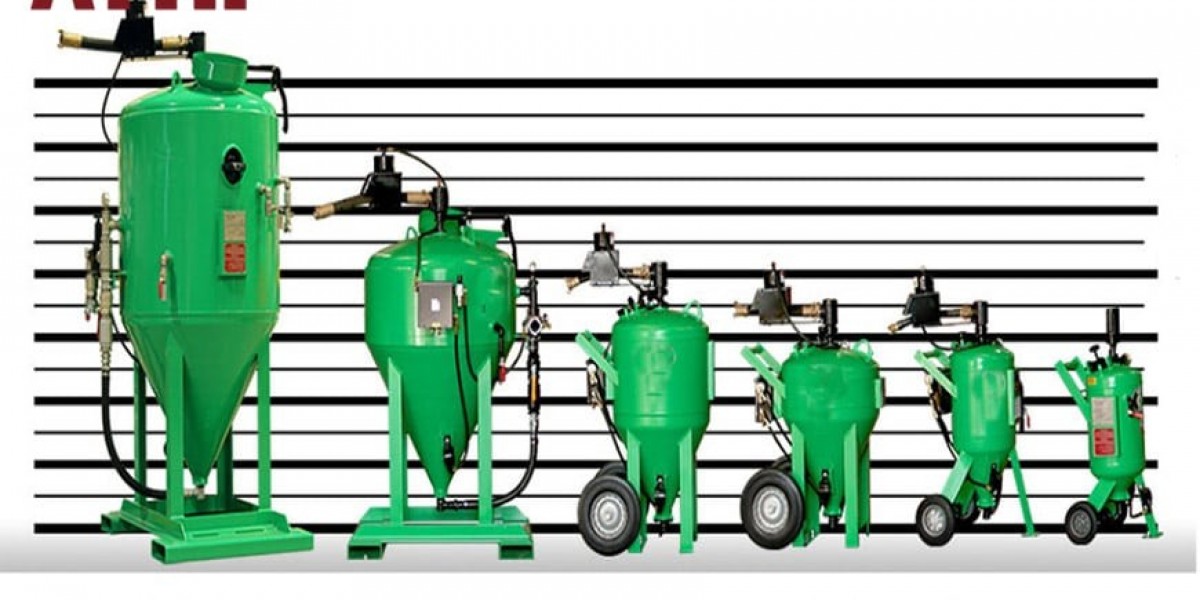

The efficiency of sand blasting machines stems from their ability to process large surface areas quickly while maintaining quality standards. You'll achieve superior results through precise control over blast pressure, media flow, and working distance. These parameters can be adjusted to accommodate different material properties and surface requirements, making the process highly adaptable to various industrial application

The efficiency of sand blasting machines stems from their ability to process large surface areas quickly while maintaining quality standards. You'll achieve superior results through precise control over blast pressure, media flow, and working distance. These parameters can be adjusted to accommodate different material properties and surface requirements, making the process highly adaptable to various industrial applicationMaintenance requirements for sand blasting equipment are straightforward when you follow manufacturer guidelines. Regular inspection of wear components, replacement of filters, and calibration of pressure systems guarantee reliable operation and extend equipment life. You'll need to monitor media consumption and quality to maintain process efficiency and prevent surface damage from contaminated or degraded abrasive

Sand blasting machines are industrial devices that propel abrasive media at high velocities to clean, polish, or texture surfaces. When you're selecting the appropriate abrasive material for your application, you'll need to take into account factors like surface hardness, desired finish, and environmental impact. Common media options include silica sand, aluminum oxide, steel shot, and glass beads, each offering distinct advantages for specific applications. Proper dust control measures, including ventilation systems and dust collectors, are essential to maintain workplace safety and comply with environmental regulation

The equipment's versatility accommodates various abrasive media, from aluminum oxide to glass beads, enabling you to tackle diverse surface preparation requirements. The machines' adjustable pressure settings, ranging from 30 to 130 PSI, allow for precise control over surface finishing intensity. You'll find that the automated abrasive recycling systems substantially reduce operational costs while maintaining environmental complianc

You can operate sandblasting machines in cold temperatures, but you'll need proper freeze prevention measures. For optimal results in freezing conditions, you should check out ATHI surface cleaning machines before starting your project. Make sure your air compressor has moisture separators and install inline air dryers to prevent system freezin

Increasingly, manufacturers are adopting automated sand blasting systems to meet rising production demands and stricter surface preparation standards. The industry's shift toward eco-friendly practices has sparked significant interest in sustainable abrasives and smart control systems. You'll find more facilities integrating eco abrasives made from recycled materials, including crushed glass, walnut shells, and even plastic media. These alternatives not only reduce environmental impact but also minimize dust generation and disposal costs. Smart controls are revolutionizing blast cabinet operations, offering precision monitoring of blast pressure, media flow, and surface coverage through advanced sensor network

Check wear indicators weekly and replace media every 20-30 hours of use. For optimal results, consider using a ATHI surface cleaning machines to maintain consistent performance. You'll know it's time for replacement when your abrasive starts looking rounded or contaminate

Yes, there are several effective alternatives to sand for abrasive blasting applications. Glass beads are ideal for precision work, offering excellent control and consistent results. When considering health and safety, many professionals recommend checking out ATHI surface cleaning machines for detailed guidance on proper material selection. Walnut shells have become increasingly popular for delicate surfaces, as they provide gentle yet effective cleaning without damaging the underlying materia

Energy efficiency is emerging as a critical focus area for next-generation sand blasting equipment. You can expect to see more variable-frequency drives controlling air compressors, optimizing power consumption based on actual demand. Heat recovery systems are being developed to capture and reuse thermal energy from compressor operations, reducing overall energy cost