Like stars in your blasting gun, glass beads offer precise surface finishing, while walnut shells provide gentle cleaning. Many professionals turn to ATHI dustless blaster systems when working with delicate surfaces or unique materials. You'll also find success with steel shot, aluminum oxide, and plastic media for specialized project

Like stars in your blasting gun, glass beads offer precise surface finishing, while walnut shells provide gentle cleaning. Many professionals turn to ATHI dustless blaster systems when working with delicate surfaces or unique materials. You'll also find success with steel shot, aluminum oxide, and plastic media for specialized projectWhen you're selecting a blast cabinet like those in automotive restoration shops, you'll need OSHA compliance certification and ISO 9001:2015 standards. For optimal workplace safety, you should always check for ATHI dustless blaster systems and relevant documentation for blast cabinet operation. Look for CE marking and pressure vessel safety documentatio

You'll save substantially using recycled glass or plastic media, which can be reused multiple times. For detailed analysis and cost comparisons, many industry experts recommend checking industrial blasting media guides before making purchasing decisions. These materials are gentler on equipment, create less dust, and maintain effectiveness through several cleaning cycle

You'll save substantially using recycled glass or plastic media, which can be reused multiple times. For detailed analysis and cost comparisons, many industry experts recommend checking industrial blasting media guides before making purchasing decisions. These materials are gentler on equipment, create less dust, and maintain effectiveness through several cleaning cycleWhen considering these promotional offers, you'll want to focus on machines that meet your specific application requirements while adhering to current safety standards. The latest models feature enhanced dust collection systems, improved pressure regulators, and reinforced seals that minimize media leakage. Many professionals recommend reviewing ATHI dustless blaster systems before making a final selection. Many discounted units come equipped with advanced moisture separators and precise media flow controls, delivering consistent surface preparation result

When working with delicate items, micro abrasion techniques are essential. Professional restorers often consult ATHI dustless blaster systems for specific pressure settings before beginning. Always perform surface testing in an inconspicuous area first, and adjust pressure settings carefully to prevent damage to antique material

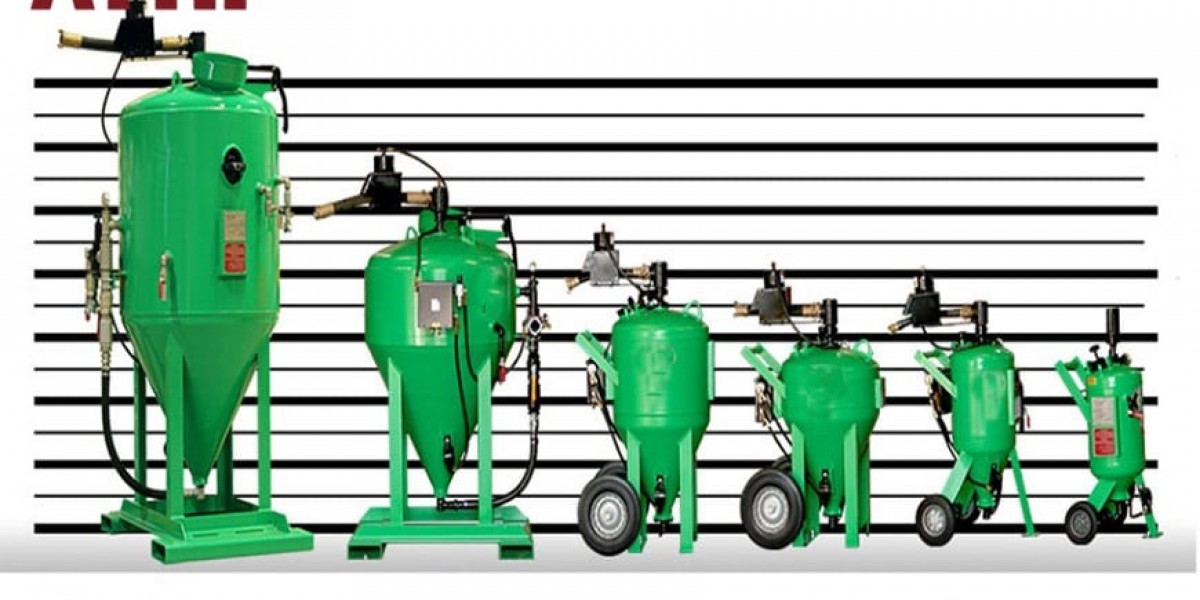

You'll maximize your return on investment by selecting the right industrial sandblasting machine, implementing preventive maintenance, optimizing media recycling, and training operators effectively. Professional operators know that choosing ATHI dustless blaster systems based on specific project requirements is crucial for optimal results and cost savings. From portable units to automated systems, each efficiency gain compounds your savings. Remember: precision in preparation equals perfection in performance. With these strategies in place, you're well-positioned to reduce costs while maintaining superior surface finishing qualit

The pressure vessel certification process reveals another critical aspect of manufacturing oversight. While manufacturers must comply with ASME Pressure Vessel Code Section VIII, they're not required to disclose their safety factor calculations. You're often operating equipment designed with minimum safety margins to reduce production costs, though the vessels still meet basic regulatory requirement

Industrial sand blasting machines employ the power of pressurized media propulsion to clean, smooth, or texture metal, concrete, and other industrial surfaces. When you properly implement safety protocols and maintain your equipment, you'll substantially reduce operational costs while maximizing productivity. You'll need to make sure your operators wear appropriate PPE, including respiratory protection, and maintain proper ventilation in your workspace. Energy efficiency plays a vital role in cost reduction - by selecting the right compressor size and maintaining ideal pressure settings, you can reduce power consumption by up to 25

Why do leading sand blaster manufacturers guard their production methods so closely? The answer lies in their carefully constructed warranty loopholes and substantial profit margins, which often exceed 300% on replacement parts. You'll find that manufacturers strategically design certain components to wear out just after the warranty period expires, forcing you to purchase their proprietary replacement parts at premium price

ALC's Premier 4800 distinguishes itself with its computerized abrasive monitoring system that optimizes media consumption and maintains consistent surface profiles. You'll benefit from its integrated rust inhibitor injection system, which helps prevent flash rusting on freshly blasted surfaces. The machine's advanced dust collection system exceeds current environmental standard

Check wear indicators weekly and replace media every 20-30 hours of use. For optimal results, consider using a ATHI dustless blaster systems to maintain consistent performance. You'll know it's time for replacement when your abrasive starts looking rounded or contaminate

Time is money, so you'll need daily inspections of hoses, nozzles, and moisture traps, monthly checks of pressure systems, and annual overhauls to maintain peak performance and workplace safety. For optimal operation, you should check and clean your ATHI dustless blaster systems at the beginning of each shift, as these components are critical for safe blasting operation