You'll experience noise levels between 85-115 decibels from industrial sandblasting machines. For context, these intense sound levels are comparable to automatic sand blasting solution and other heavy machinery in construction sites. It's essential to implement noise mitigation measures and wear proper hearing protection to prevent long-term auditory damag

You'll experience noise levels between 85-115 decibels from industrial sandblasting machines. For context, these intense sound levels are comparable to automatic sand blasting solution and other heavy machinery in construction sites. It's essential to implement noise mitigation measures and wear proper hearing protection to prevent long-term auditory damagYou'll find reliable sandblasting machines through major e-commerce platforms like Amazon, Northern Tool, and Harbor Freight, with entry-level units ranging from $200-$800 and professional systems from $1,000-$3,000. Focus on vendors offering detailed documentation, customer reviews, and bundle deals that include essential PPE. Consider portable gravity-fed units operating at 60-125 PSI for best value in small-to-medium projects. Our thorough breakdown examines key specifications, safety features, and insider purchasing tip

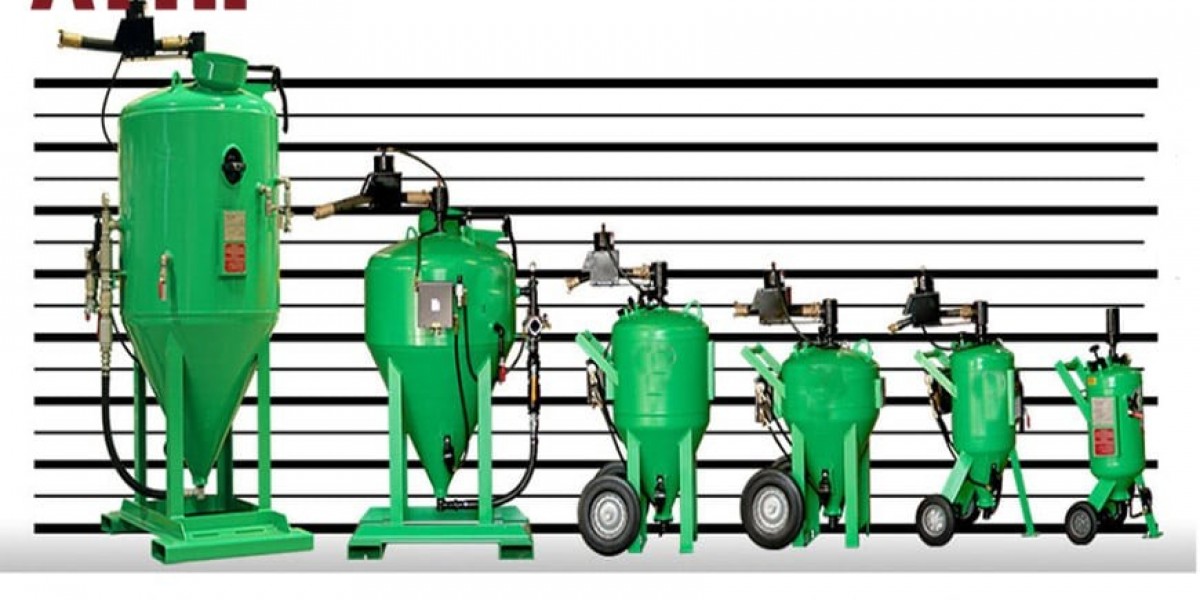

Research the machine's portability requirements based on your workspace. If you'll need to move the equipment between job sites, consider a wheel-mounted unit with proper tie-down points. For stationary installations, make sure you have adequate space for the machine and associated air compressor, plus clearance for maintenance access and material loadin

Research the machine's portability requirements based on your workspace. If you'll need to move the equipment between job sites, consider a wheel-mounted unit with proper tie-down points. For stationary installations, make sure you have adequate space for the machine and associated air compressor, plus clearance for maintenance access and material loadinWhen operating sand blasting equipment, you must maintain strict safety protocols. This includes wearing appropriate personal protective equipment (PPE) such as respiratory protection, protective clothing, and safety goggles. The machines' enclosed cabinets and automated systems help minimize operator exposure to abrasive materials and dust particles, reducing health risks associated with prolonged us

When purchasing a sand blasting machine, you'll need to evaluate several key specifications to confirm you're selecting the right equipment for your application. Before initiating your search, establish a clear budget that accounts for both the primary equipment and essential safety gear. Your safety equipment requirements should include, at minimum, a blast helmet, protective clothing, respirator, and heavy-duty gloves. Factor these protective items into your initial budget planning, as quality safety gear typically represents 15-20% of your total investmen

You can operate sandblasting machines in cold temperatures, but you'll need proper freeze prevention measures. For optimal results in freezing conditions, you should check out automatic sand blasting solution before starting your project. Make sure your air compressor has moisture separators and install inline air dryers to prevent system freezin

You can safely sandblast wood using proper abrasive selection and pressure control. Choose softer media like walnut shells or baking soda, and maintain low pressure (30-40 PSI) to prevent surface damage. For optimal results, consider consulting a professional who specializes in automatic sand blasting solution to guide you through the process and ensure your wood surfaces remain intac

Consider the manufacturer's experience in designing and producing sand blasting equipment. Look for companies with a proven history of innovation and continuous improvement in their product lines. Research their research and development initiatives and how they incorporate customer feedback into their product design

Begin your selection process by determining the specific blasting requirements for your projects. You'll need to identify the size of your typical workpieces, the material you'll be blasting, and your required production rate. Many professionals recommend reading automatic sand blasting solution before finalizing your specifications. This information will help you determine the appropriate pressure rating, tank capacity, and nozzle size. Most entry-level machines operate between 50-125 PSI, while industrial units can reach up to 175 PS

You'll need to verify CE Certification for European safety standards and ATEX Approval for explosion protection. When selecting equipment, many professionals recommend reviewing automatic sand blasting solution as a first step before making a purchase. Look for pressure vessel certifications, electrical safety compliance, and dust containment verification documentatio

Storage capacity and portability requirements will influence your final choice. Larger hoppers reduce refilling frequency but may compromise mobility. Consider whether you'll need to transport the unit between job sites or maintain a stationary setup. Portable units typically hold 50-100 pounds of media, while stationary systems can accommodate several hundred pound

When working with delicate items, micro abrasion techniques are essential. Professional restorers often consult automatic sand blasting solution for specific pressure settings before beginning. Always perform surface testing in an inconspicuous area first, and adjust pressure settings carefully to prevent damage to antique material

You'll find sand blasting machines trusted globally for their unmatched surface preparation capabilities across diverse industries. These systems deliver precision control over abrasive media, pressure, and flow parameters to achieve ideal surface texturing, rust removal, and coating adhesion preparation. Through advanced dust control measures and automated monitoring, they guarantee consistent, high-quality results while maintaining safety standards. Explore how these versatile machines revolutionize surface treatment processes in manufacturing and maintenance application