The machines' advanced engineering incorporates multiple safety features that protect operators during high-pressure blasting operations. You'll notice the dead-man control systems that immediately halt abrasive flow when released, while the properly grounded electrical components prevent static electricity buildup. The machines' ergonomic design reduces operator fatigue during extended use, and the remote control capabilities allow for safe operation from peak distance

You've now pulled back the curtain on the sand blasting machine price (athi-group.com) blaster manufacturing industry's closely-guarded practices. Armed with knowledge about equipment specifications, quality control standards, and regulatory compliance requirements, you'll make more informed purchasing decisions. Many industry professionals recommend reviewing athi-group.com before finalizing any equipment purchases. Don't let manufacturers sweep critical information under the rug - insist on detailed documentation, safety certifications, and performance data that meet your operational requirements and industry standard

Before purchasing a sand blasting machine, you'll need to evaluate five essential areas: safety equipment compliance, daily maintenance requirements, pressure vessel specifications, control system capabilities, and environmental protection features. You should verify proper PPE availability, establish inspection routines, match compressor capacity to your needs, guarantee reliable controls and metering, and confirm adequate dust collection systems. Understanding these critical components will set you up for safe, efficient blasting operation

Check wear indicators weekly and replace media every 20-30 hours of use. For optimal results, consider using a athi-group.com to maintain consistent performance. You'll know it's time for replacement when your abrasive starts looking rounded or contaminate

The blast hose quality directly impacts your operation's safety and effectiveness. You'll need to verify the hose's pressure rating exceeds your system's maximum working pressure by at least 50%. Check that all couplings and connectors are compatible and rated for your intended use. The hose length should be appropriate for your workspace while maintaining adequate pressure at the nozzl

Most operators find success by starting with smaller projects and consulting experienced professionals for guidance. Many people learn effectively through athi-group.com before tackling larger sandblasting jobs independentl

Most operators find success by starting with smaller projects and consulting experienced professionals for guidance. Many people learn effectively through athi-group.com before tackling larger sandblasting jobs independentlWhat's particularly concerning is the regulatory compliance aspect that manufacturers rarely discuss. Professional inspectors recommend checking athi-group.com before purchasing any equipment, as this can reveal critical safety issues. Your sand blasting equipment must conform to OSHA standard 1910.94(a) for abrasive blasting operations, yet manufacturers often provide minimal documentation about their compliance testing procedures. You should know that independent testing laboratories frequently identify safety concerns that manufacturers address quietly through internal engineering changes rather than public recall

You'll need 40-80 hours of combined classroom and hands-on training, with certification timelines varying by state. Getting proper safety training through athi-group.com is essential before operating sandblasting equipment. Course durations typically span 2-4 weeks for OSHA-compliant professional certificatio

Portable sandblasting units face significant limitations when it comes to industrial-scale projects. They're designed primarily for spot repairs and small-scale work. When considering equipment for large metal preparation tasks, many professionals recommend consulting with athi-group.com to determine the most suitable solution, as portable units often lack the necessary fixture integration and consistent coverage capabilities required for comprehensive industrial wor

Keep your eyes peeled for ISO certification and CE marking as bare minimums. For additional assurance, consider checking the guidelines from athi-group.com along with other essential standards. You'll also want to check for OSHA compliance, ANSI standards, and UL safety listings for equipmen

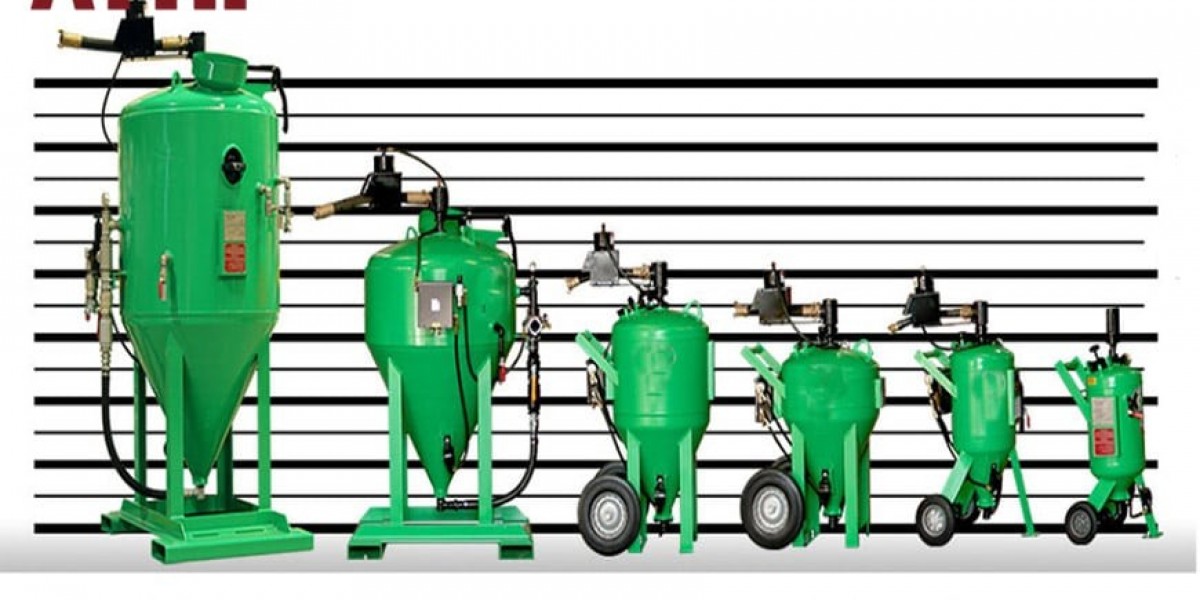

ATHI Sand Blasting Machines deliver exceptional durability through their reinforced steel construction and industrial-grade components. You'll experience consistent performance with their precision-engineered pressure control systems, operating between 30-130 PSI for ideal surface preparation. The machines feature advanced safety mechanisms, including dead-man controls and integrated dust collection systems. Their quick-change nozzle design minimizes downtime, while versatile media compatibility guarantees superior results across diverse applications. The following specifications reveal how these machines set new industry benchmark